Introduction to ENCY Tuner

Application area:

ENCY Tuner is a software designed for machine operators working with CNC machines and industrial robots. As part of the ENCY X ecosystem, it focuses on managing NC programs at the shop-floor level. ENCY Tuner enables users to simulate, fine-tune, and re-engineer NC code (G-code) before sending it to the machine.

ENCY Tuner provides the following functions to accomplish these tasks:

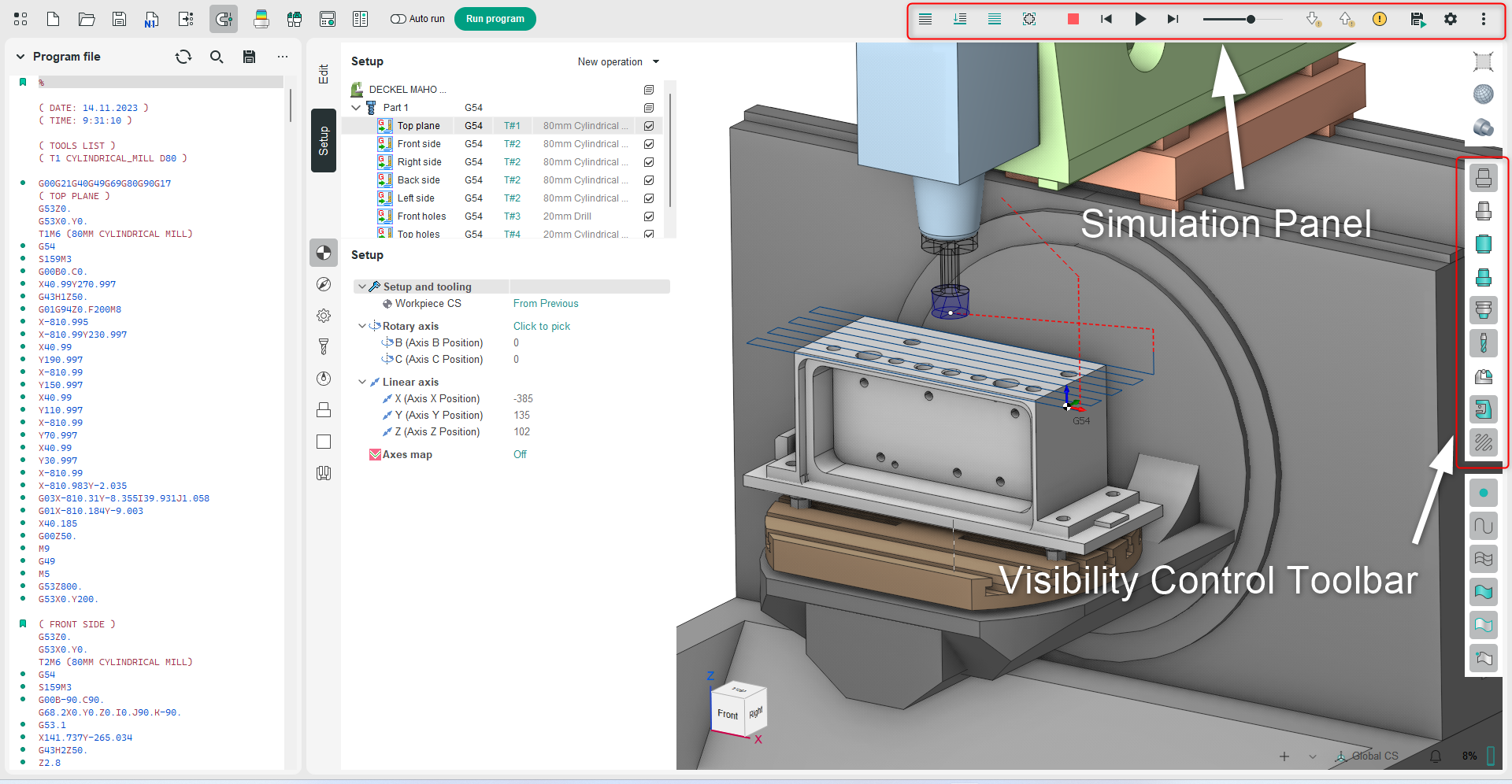

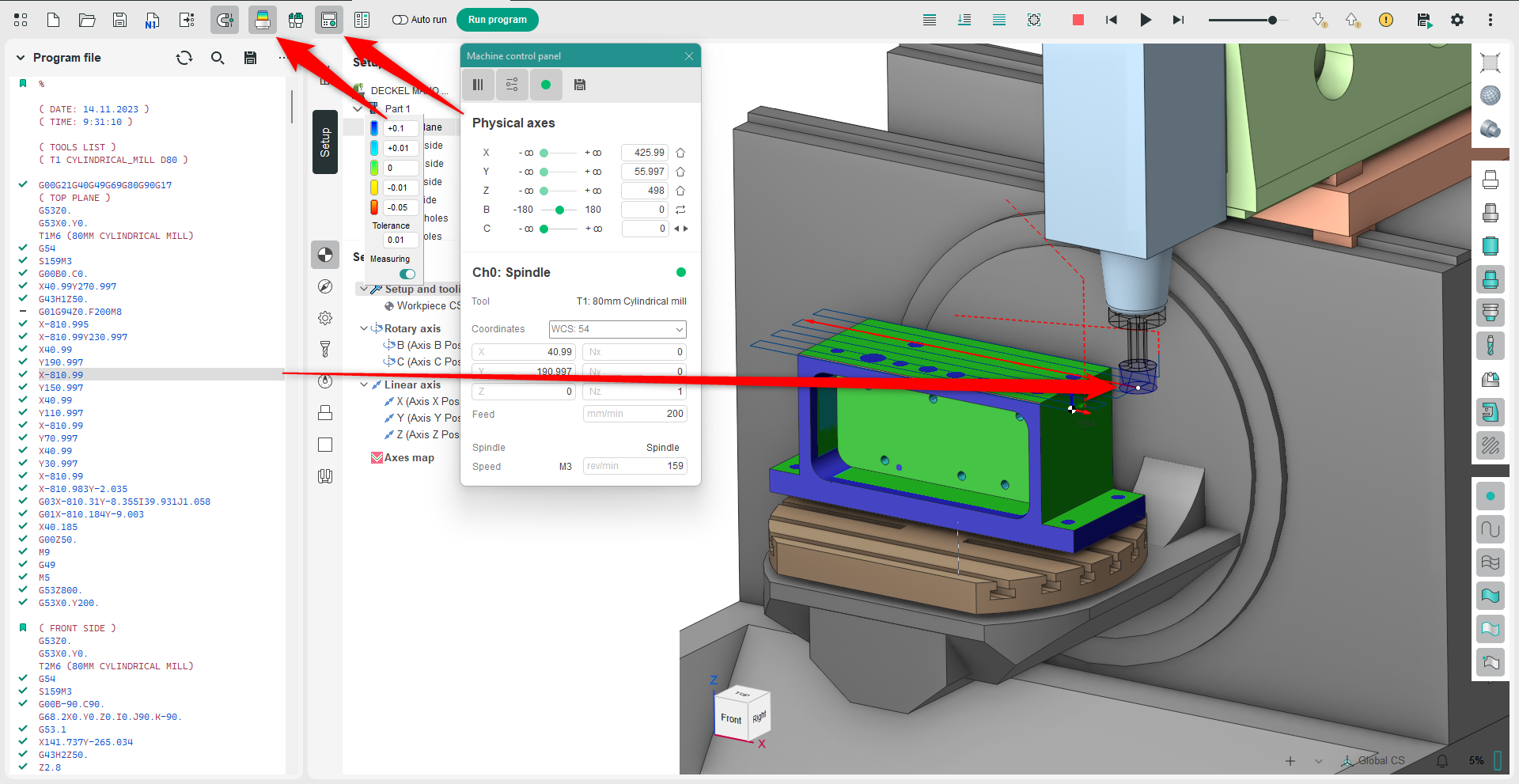

It simulates NC program execution using an extensive set of monitoring tools. It tracks potential failures, including collisions, and the state of the workpiece after each operation, including unmachined areas part gauges. The system supports subtractive, additive, and hybrid process simulations using high-quality voxel or solid modeling. See more.

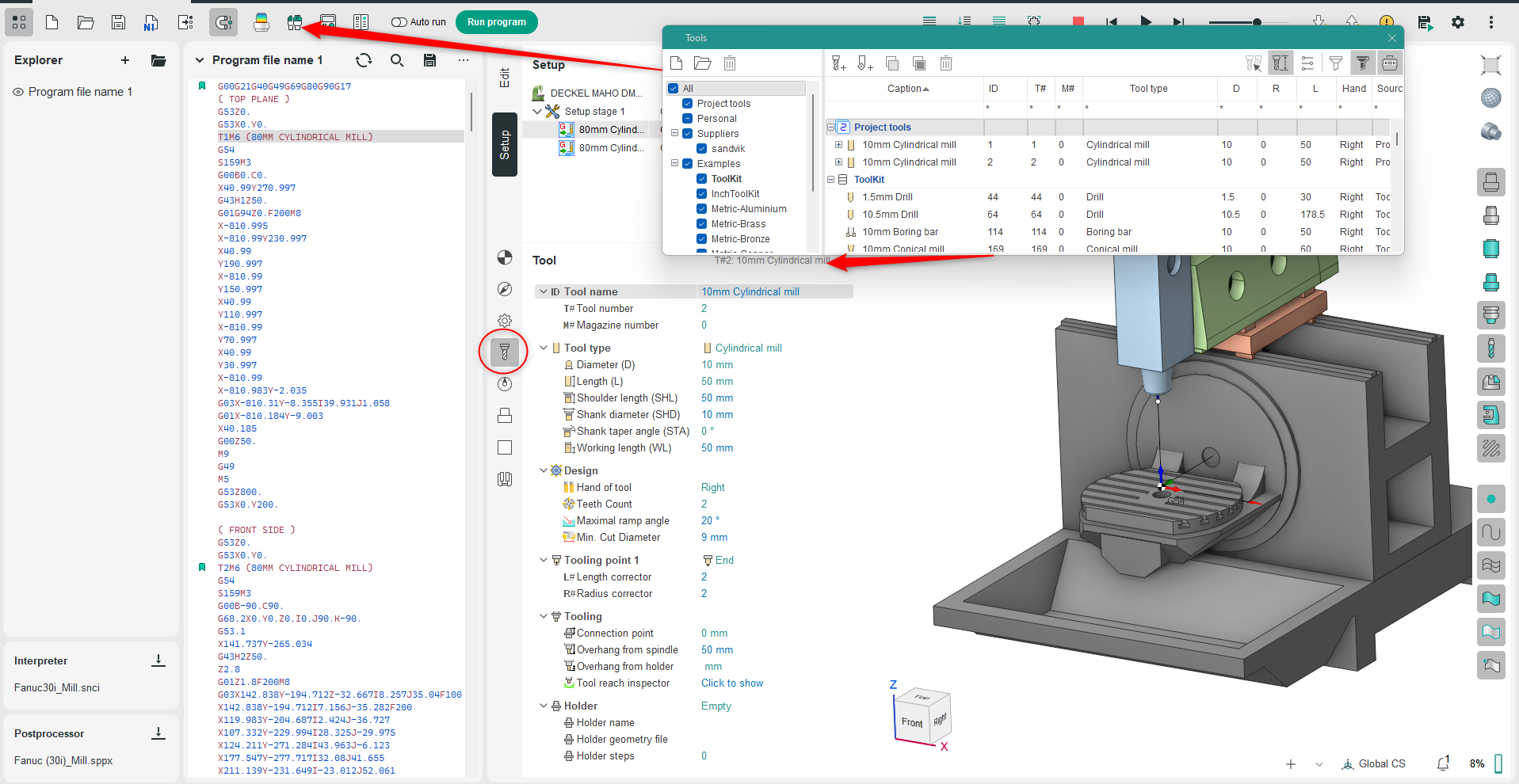

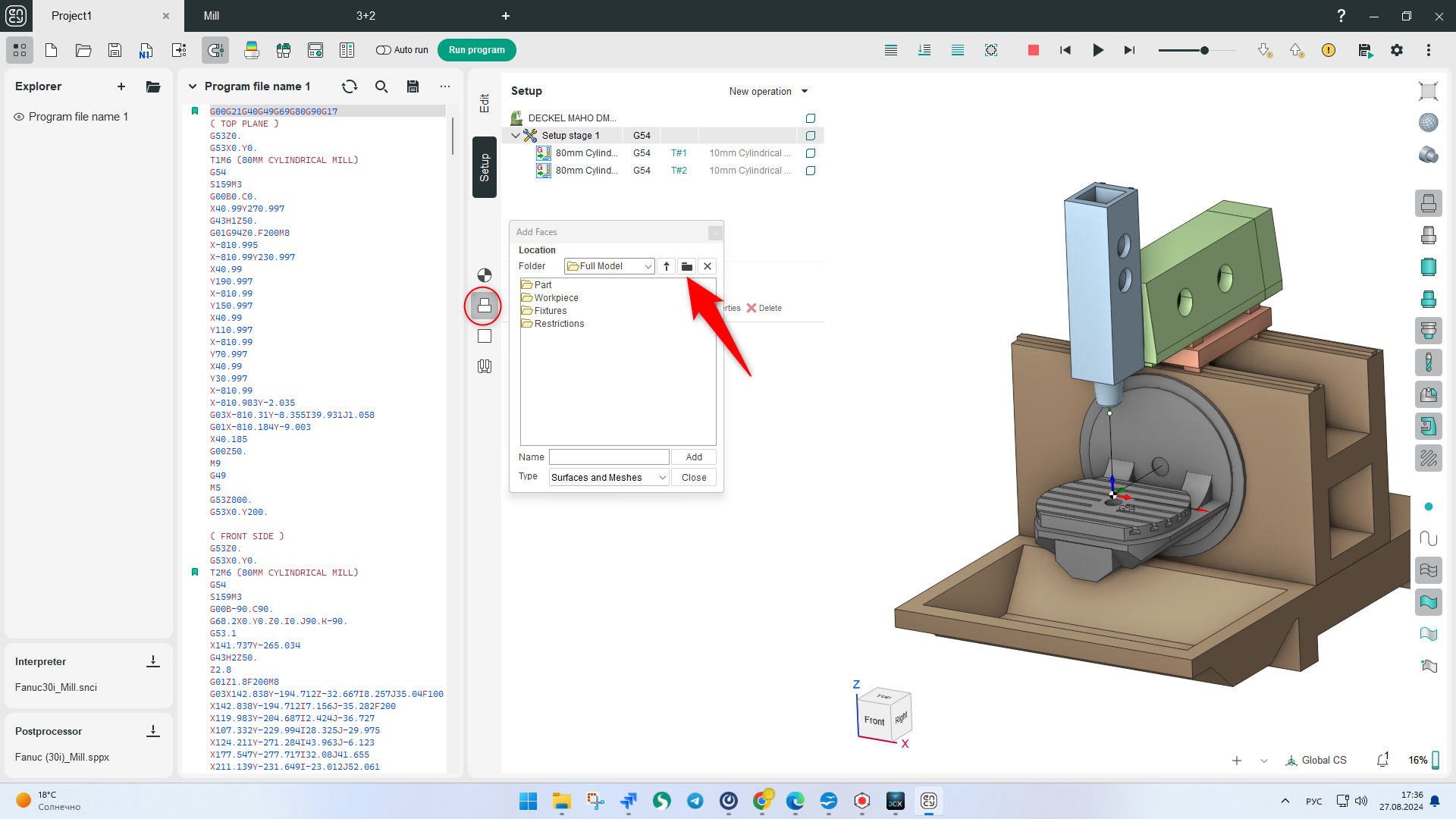

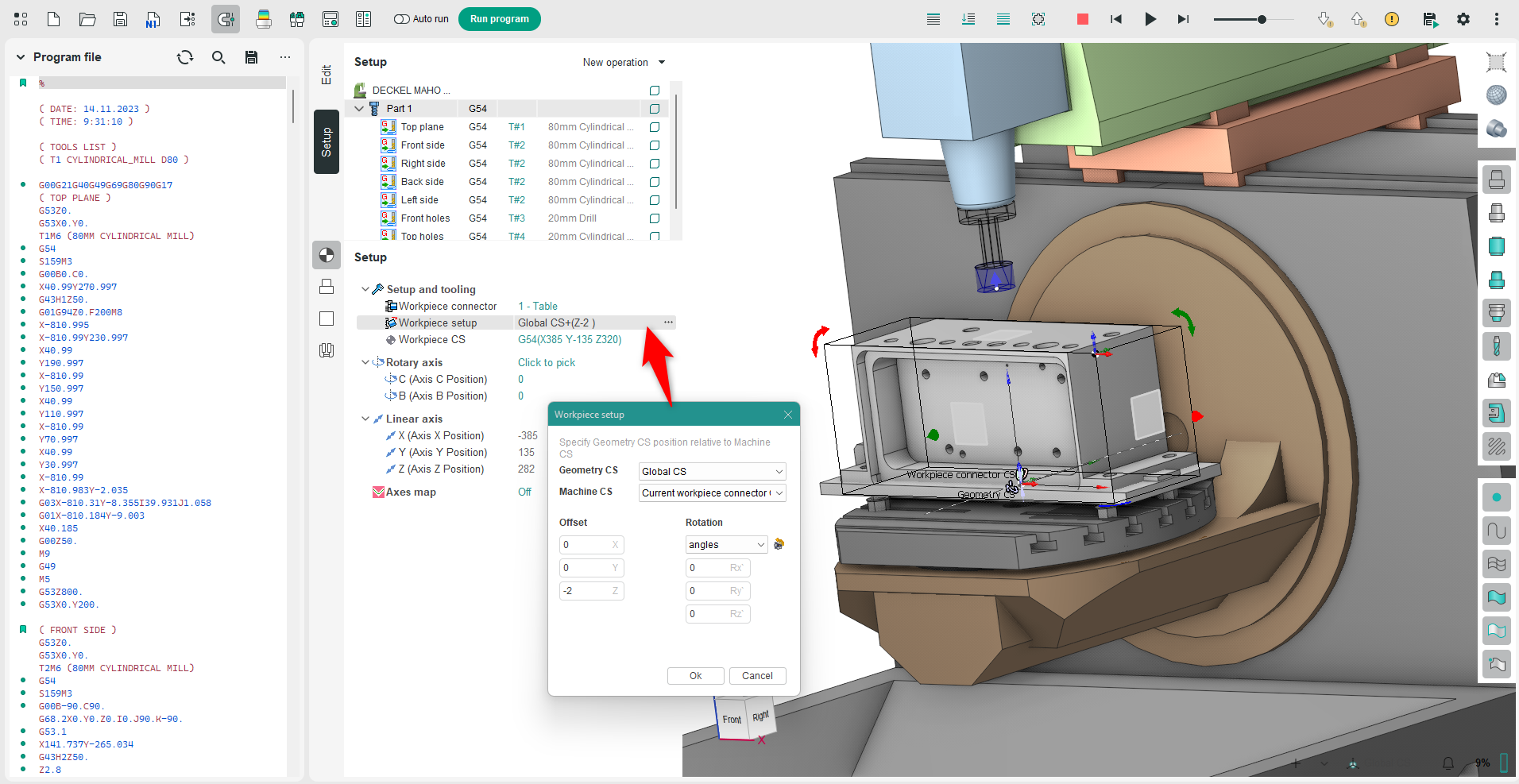

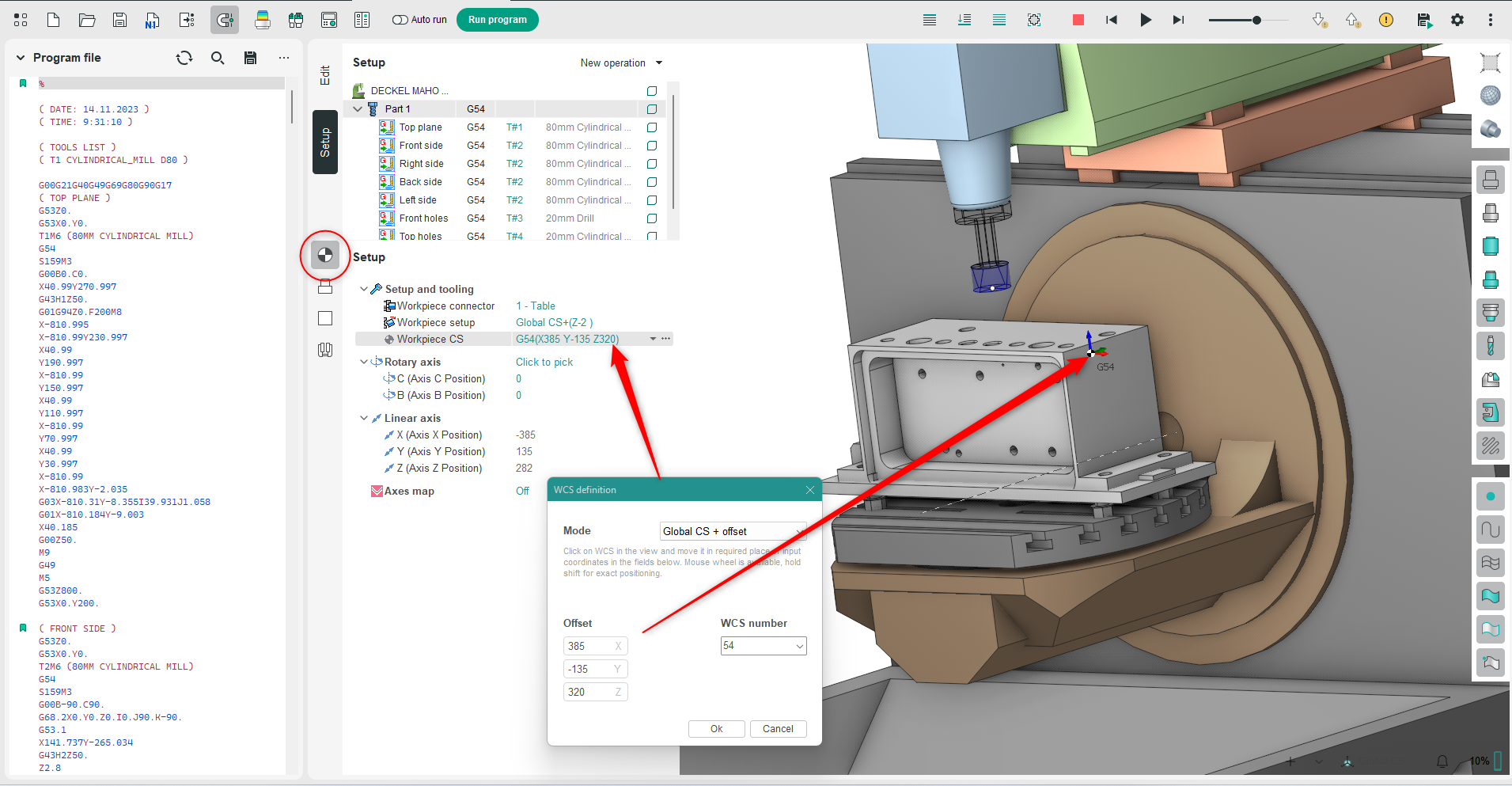

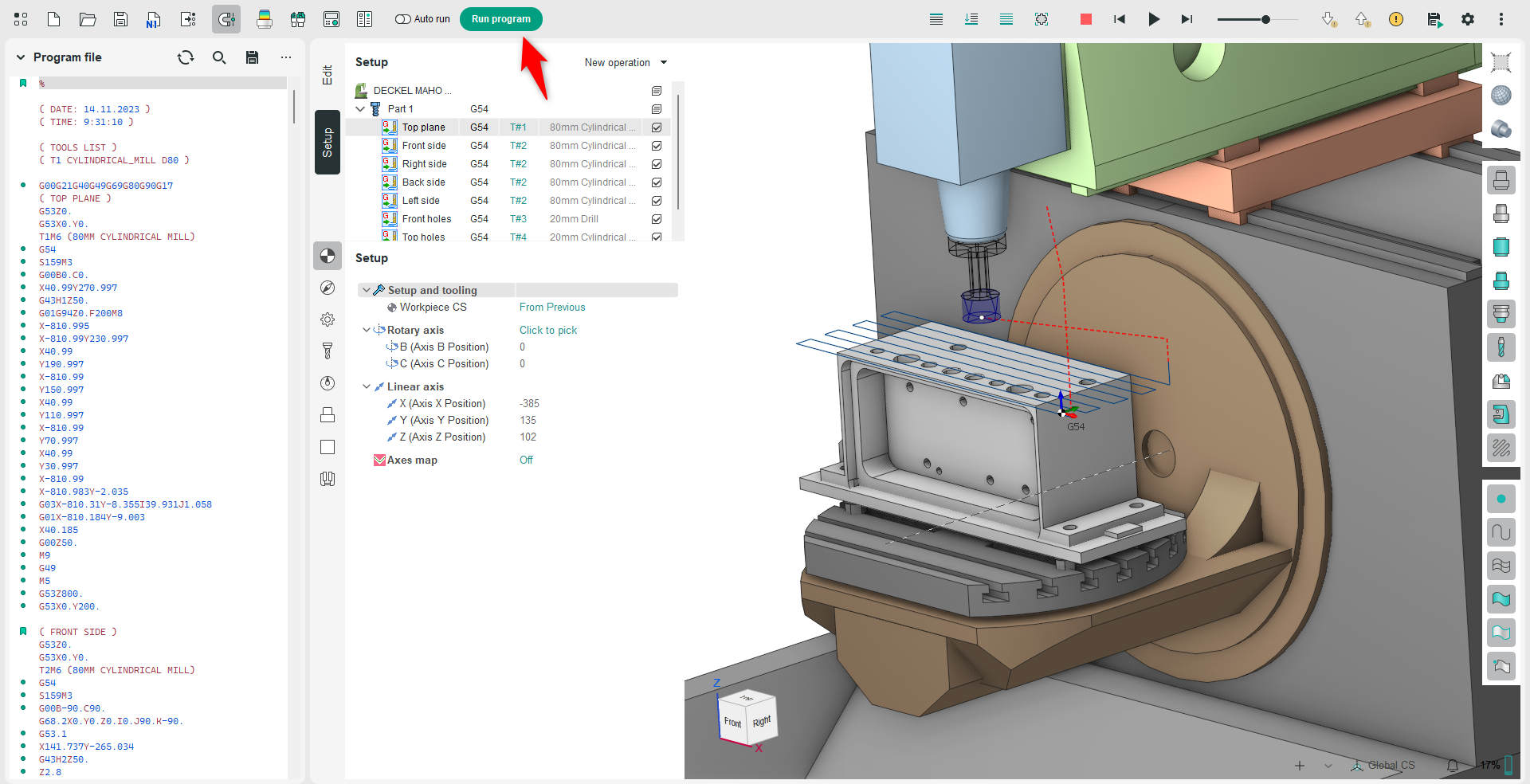

Users can build digital twins of the manufacturing systems with 3D models of equipment, tooling, and workpieces. These digital twins can serve as templates for future simulations with different NC programs.See more.

ENCY Tuner displays the final result of the simulated machining process and enables users to compare it with the target 3D model of the part. See more.

The software displays the positions of machine axes throughout the simulation process. See more.

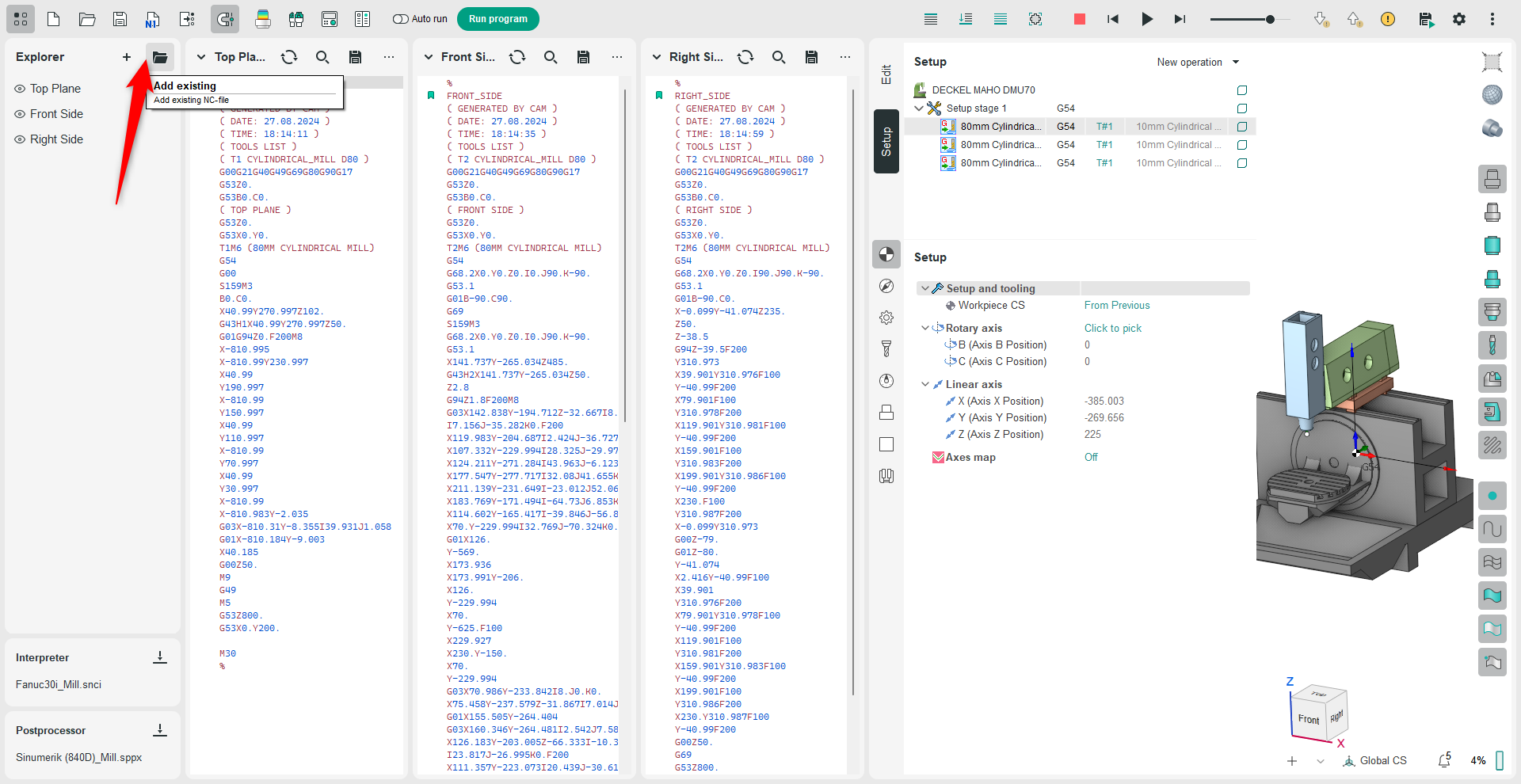

Users can open and manage several NC program files in parallel, using functions such as file addition, removal, replacement, and renaming. See more.

ENCY Tuner allows users to analyze and compare the code in two different NC program files to track G-code revisions, their changes or inconsistencies. See more.

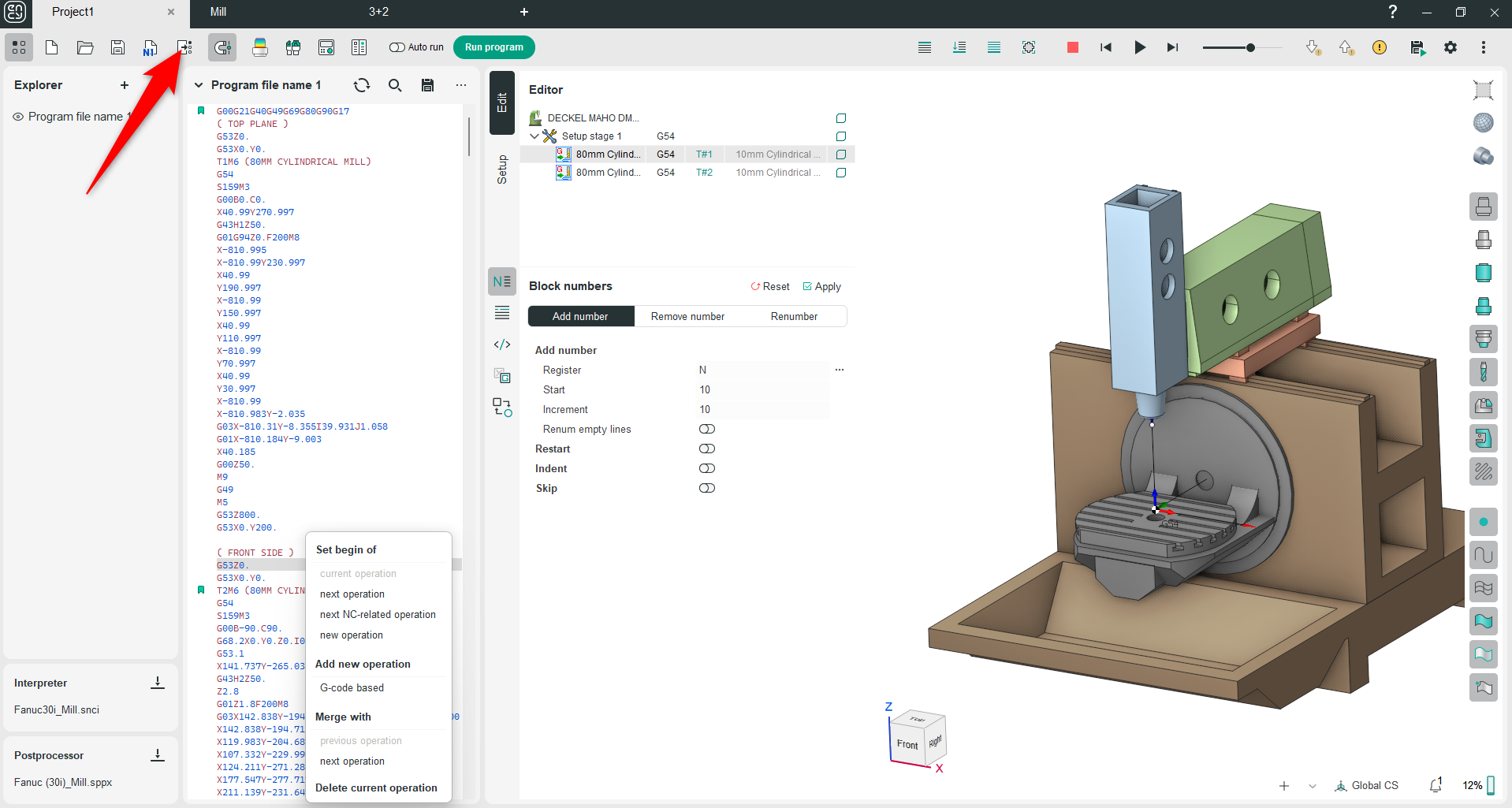

The system allows manual command-level editing within NC programs. See more.

ENCY Tuner provides live toolpath visualization throughout the NC code development process. See more.

ENCY Tuner simplifies program structuring by auto-inserting commonly used address templates such as block numbers. See more.

The system allows automated editing of command structures, including address fields and corresponding values. When editing addresses automatically, it ensures intelligent handling of dependent references such as block numbers. See more.

Users can retrieve detailed information on allowable ranges for command values, like position coordinates. See more.

The software performs toolpath transformations such as shifting by a specified value, rotating by a given angle, and applying mirror symmetry. See more.

Users can reformat control programs for use with alternative CNC control systems. See more.

ENCY Tuner lets users to create CAM project structures from existing NC code to enable further operations in ENCY ecosystem. Such it useful for teams with large libraries of old G-code from outdated systems.

Workflow:

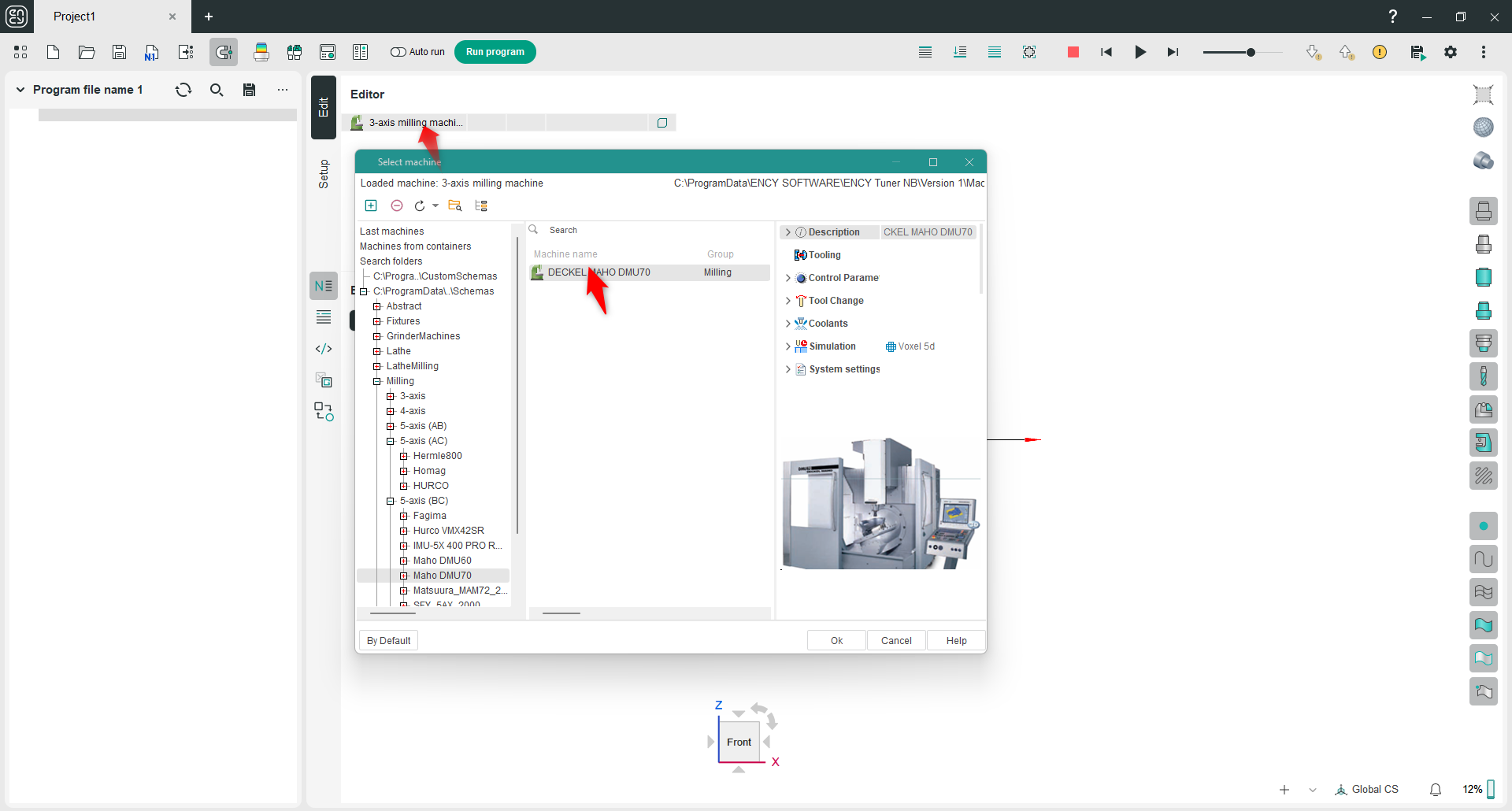

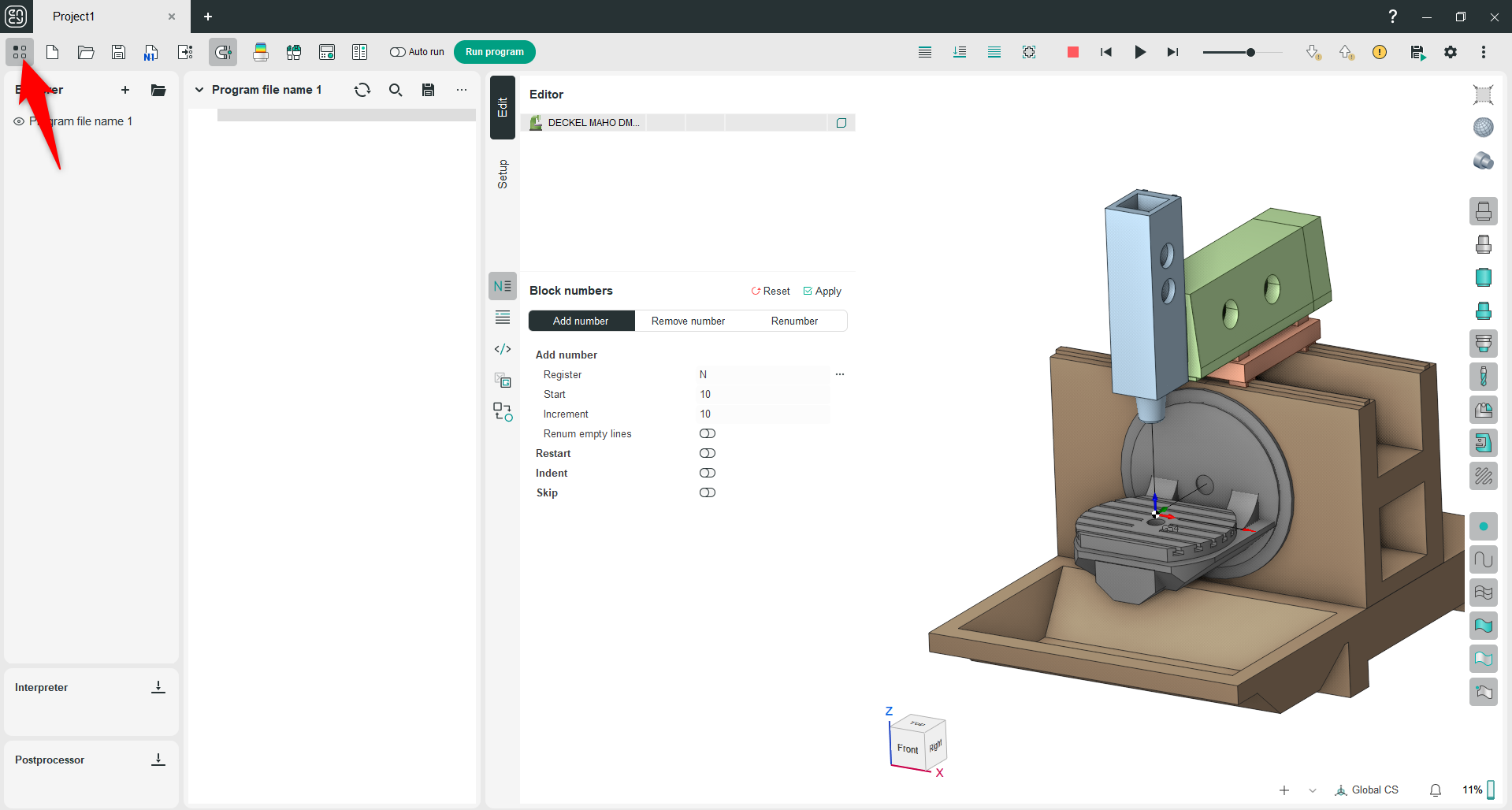

Perform all operations with NC programs within the ENCY Tuner project environment. Each project utilizes:

one or more NC programs (See more);

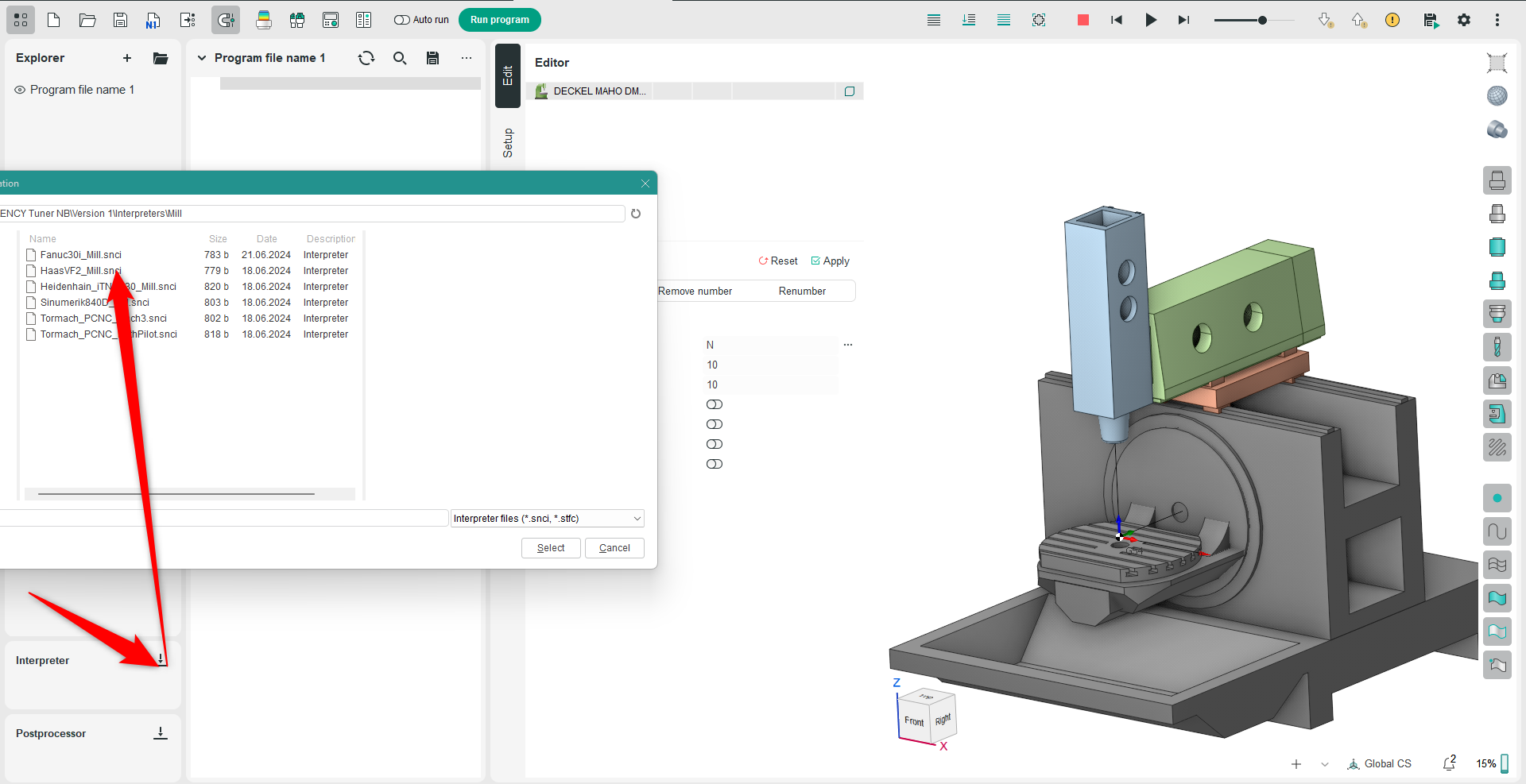

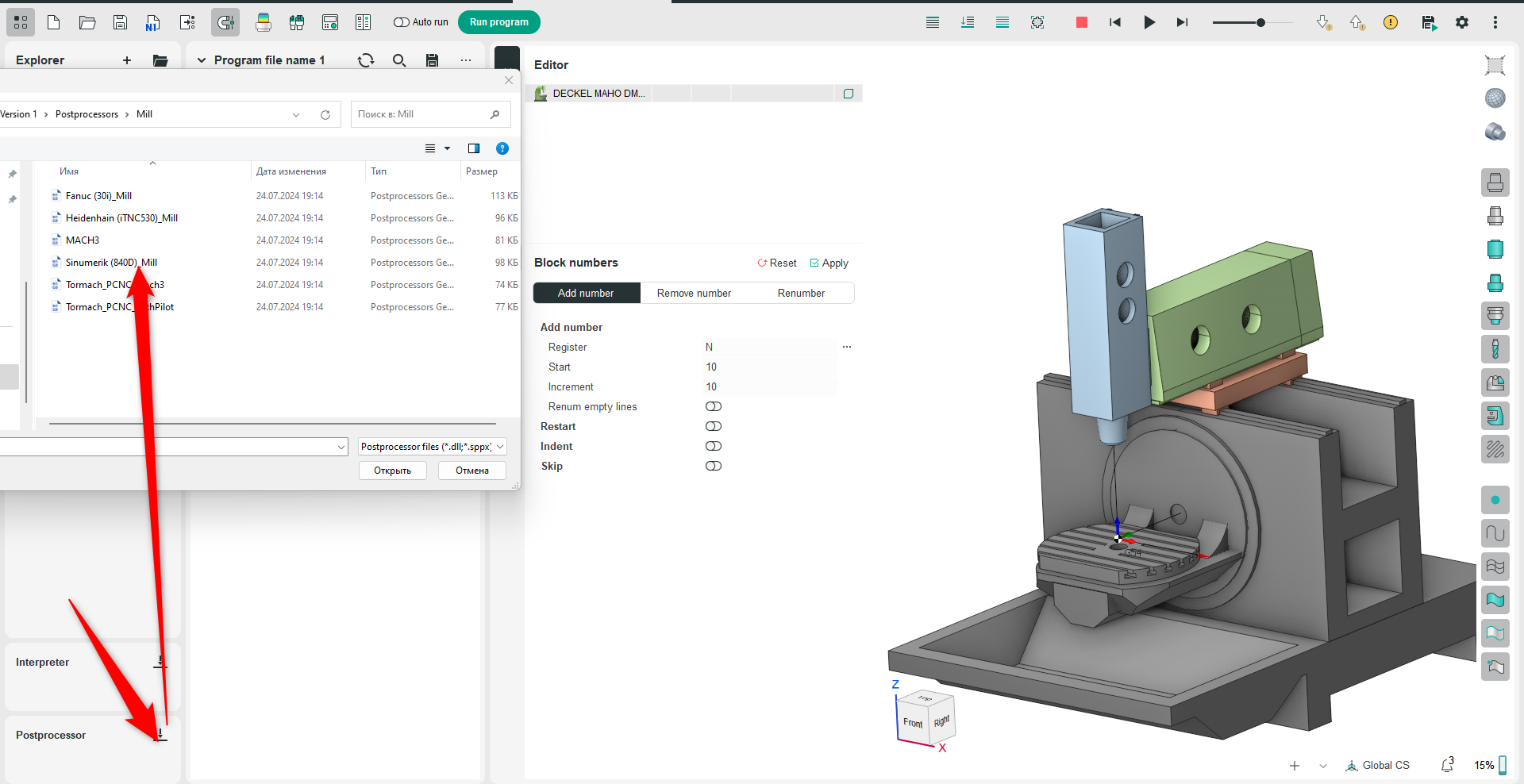

an interpreter to translate G-code into technological operations and CLDATA commands (See more);

a postprocessor to transform edited operations into G-code (See more);

tools for editing NC programs (See more);

a technology tree with tools for editing technological objects (See more);

tools for simulating programs and technological operations (See more).

According to the defined objectives, work in ENCY Tuner can follow these procedures:

Creating a new NC program.

When ENCY Tuner starts, it automatically creates a new project, enabling the creation of a new NC program from scratch. The project automatically opens a new Code Editor Panel window. The Main Panel loads the machine used in the last project.

Handling an existing NC program.

The process in this case is similar to the previous one, except for the following point:

Operating with a CAM system project.

You can utilize NC Tuner to debug the NC program within a configured CAM system project environment.

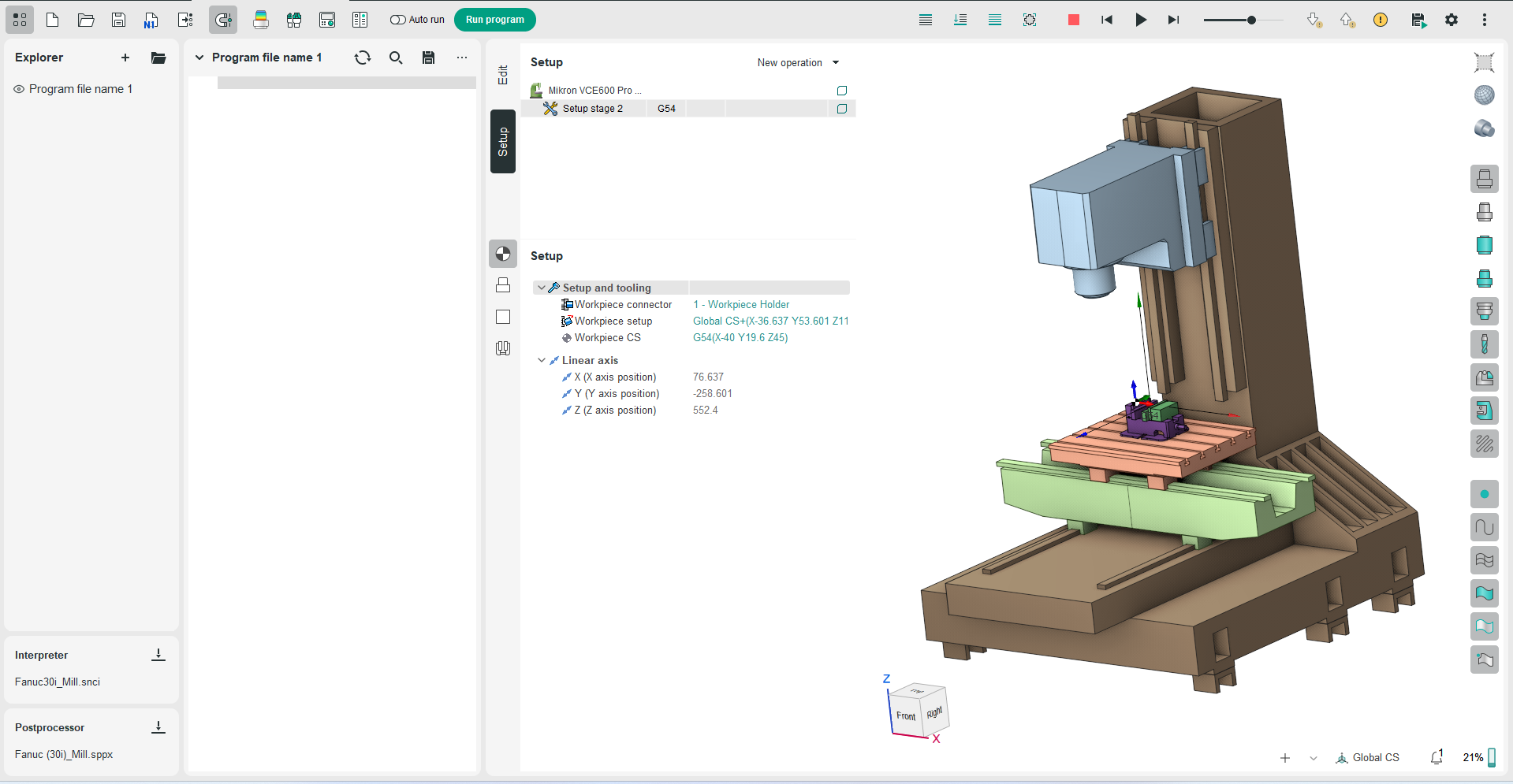

Creating a new project using a CAM system setup file.

If you want to debug the NC program using a previously defined template from the CAM system, load the setup file with a .stms extension. This file contains a template with specific configurations, such as tools and fixtures, for machining similar parts.