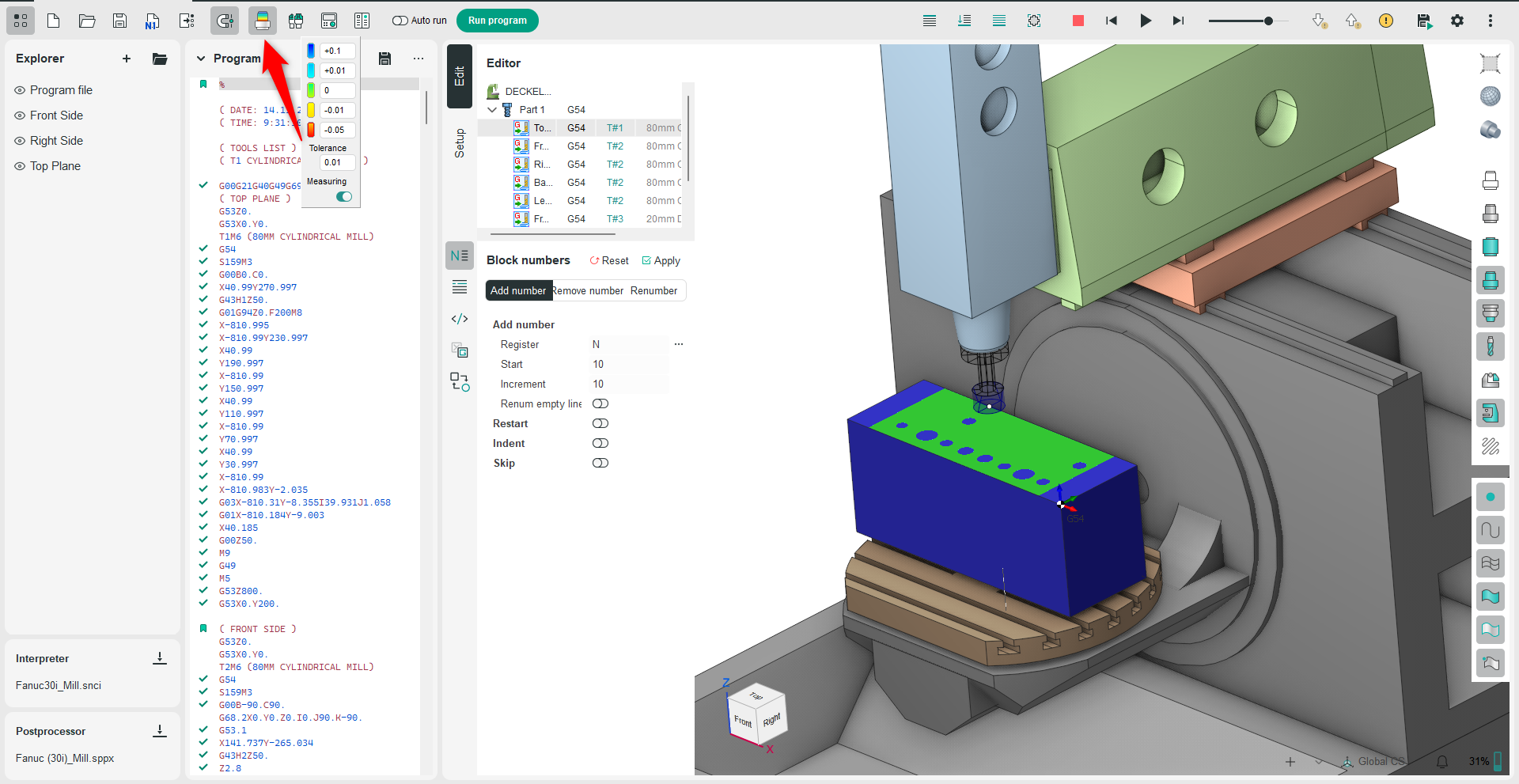

Project management panel

Application Area:

Includes tools for generating and visualizing project operations, their settings, and NC programs.

Toolkit:

Postprocessor.

Generates a new NC program based on the technological operations displayed in the Main Panel window. Ensure that the post-processor is loaded in the Explorer Panel. Clicking the button opens the post-processing dialog. The view, its parameters, and commands are the same as in the CAM system. See more.

Split.

Generates technological operations for display in the Main Panel window using the loaded NC program files. Ensure that the interpreter file is loaded in the Explorer Panel. The function segments the loaded NC codes by tool numbers and zero offset addresses. Each appearance of a new tool and a new zero offset address in the program indicates the start of a new operation. However, if a tool change and zero offset assignment occur next to each other in the NC program, they are processed as a single operation. You can adjust the separation of technological operations using the context menu commands in the NC Code Editor Panel.

Smart Snap.

The Smart snap button enables / disables snapping to objects in the graphics window. This is useful when docking parts or fixtures to the existing machine nodes or when creating new or editing existing coordinate systems, etc.The functionoperates in the same way as in the CAM system. See more.

Verify Compare.

Machining result with part compare can be activated. It allows you to display the difference between the original part and the result of machining in the form of a color scheme where each color is associated with a specific deviation range between the compared elements. The function operates in the same way as in the CAM system. See more.

Tools.

The purpose of the Tools window is to view and edit project tools, operations tools, create and fill tool libraries. The function operates in the same way as in the CAM system. See more.

Machine Control Panel.

Machine axes control window allows you to watch and modify the current values for all machine / robot coordinates. To show this windows you need to click button on the main toolbar. It is helpful when analyzing tool path in simulation mode, when constructing of manual approaches or when determining the initial position of the machine to calculate the technological operation. The function operates in the same way as in the CAM system. See more.

Comparer.

Provides a feature to compare the texts of two NC programs displayed in separate NC Code Editor Panels. Differences between the two NC programs appear as colored highlights—red in the left panel and green in the right panel. The following commands are available in the NC program comparison mode:

Auto Run.

When the feature is active, changing the NC program text will trigger an automatic recalculation of the operations displayed in the Main Panel window

Run Program.

Pressing the button calculates the operations in the Main Panel window, displaying their trajectories. As a result, the operation status changes, and labels appear in each block of the NC program: