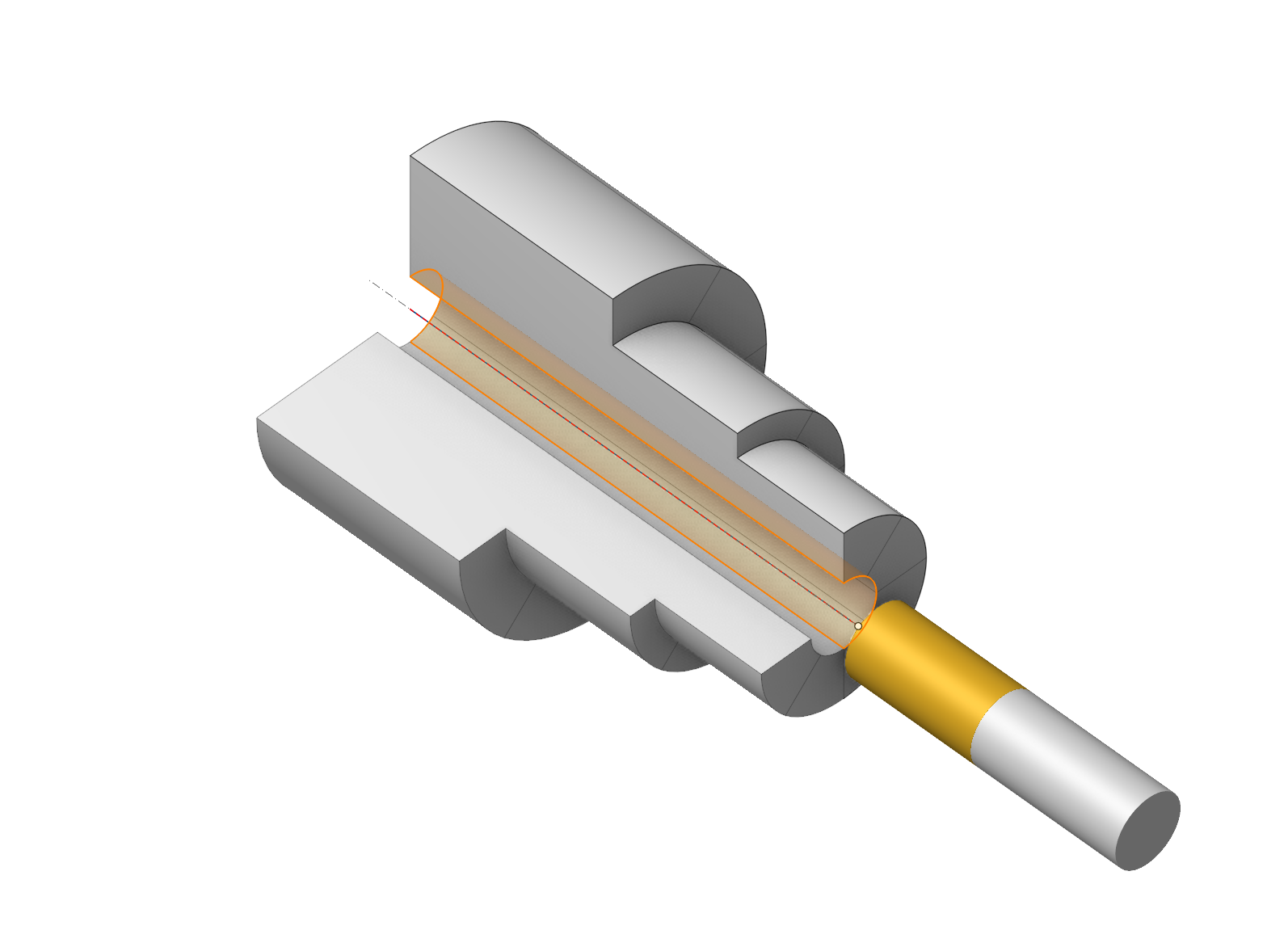

Lathe hole machining operation

Application area:

The hole machining operations are designed for drilling, centering, boring, countersinking, tapping, thread milling and hole pocketing. It can machine holes that are not lying in the same plane and that are not lying in orthogonal planes. The operation can be used both for the machining of holes in a model, or for pre-drilling of the tool plunge points for the pocketing and operations.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Job assignment:

Center. Create hole by center point.

Create. Create hole by coordinates input. See more

Recognize. Automatically recognize holes in the part. See more

Pattern. Create holes array by pattern. See more

Properties. Displays the properties of an element. You can also call this menu by double clicking on an item in the list. See more

Sorting. Sorting using some parameters to sort holes list. See more

Delete. Removes an item from the list.

Restrictions. It allows you to restrict areas that should not be machined. See more

Strategy:

This parameter group works similarly to the Hole machining operation. See more

Links/Leads:

In the Links/Leads tab, you define the parameters for rapid movements. These movements include tool approach from the tool change position, engage to the start of the working stroke, retraction after the final cutting motion, transitions between working passes, and return to the tool change point. You can configure the sequence of movements along the coordinates, the trajectory of these motions, and the magnitude of displacements.

Feeds/Speeds:

Using this dialogue the user can define the spindle rotation speed; the rapid feed value and the feed values for different areas of the toolpath. Spindle rotation speed can be defined as either the rotations per minute or the cutting speed. The defining value will be underlined. The second value will be recalculated relative to the defining value, with regard to the tool diameter. See more

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more

Part:

A Part is a group of geometrical elements that defines the space to check for gouges. See more

Workpiece:

A workpiece model of an operation defines the material to be machined. See more

Fixtures:

As the Fixtures the fixing aids such as chucks, grips, clamps, etc., and the restriction areas of any other nature are usually specified. See more

See also: