Feeds/Speeds

Application Area:

Using this dialogue the user can define the spindle rotation speed; the rapid feed value and the feed values for different areas of the toolpath. Spindle rotation speed can be defined as either the rotations per minute or the cutting speed. The defining value will be underlined. The second value will be recalculated relative to the defining value, with regard to the tool diameter.

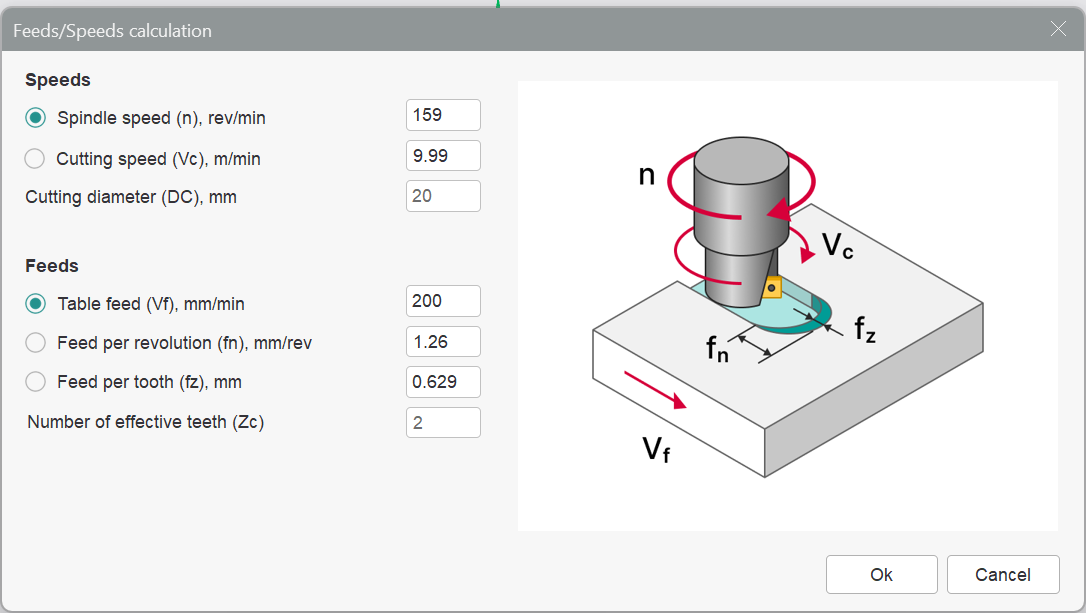

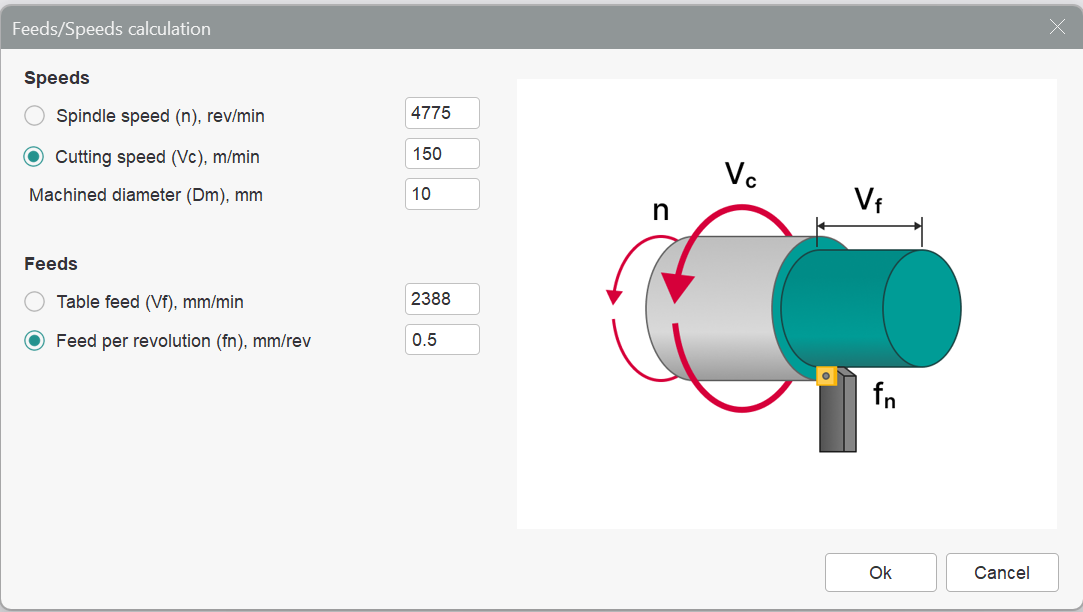

Feeds/Speeds (Calculate).

The calculator enables users to set and automatically calculate spindle speeds and feed rates.

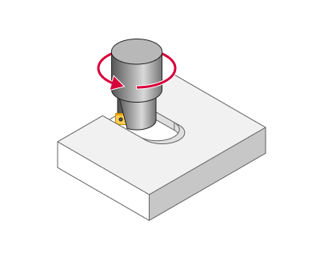

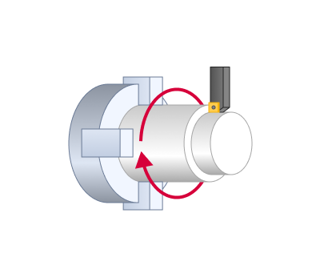

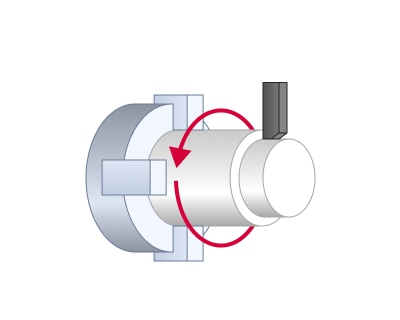

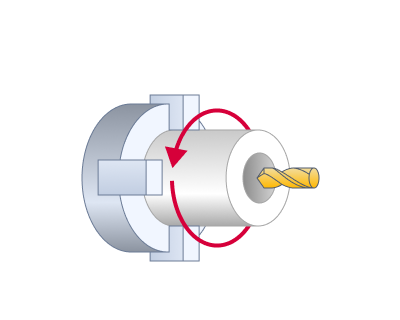

Spindle.

This parameter group configures the spindle rotation properties.

Coolant:

This parameter group controls the coolant supply to the cutting area. The postprocessor uses these parameters to generate the appropriate commands for enabling and disabling coolant flow in the NC program. Users can define coolant supply methods and configure their parameters in the Coolants section under the Equipment tab. See more.

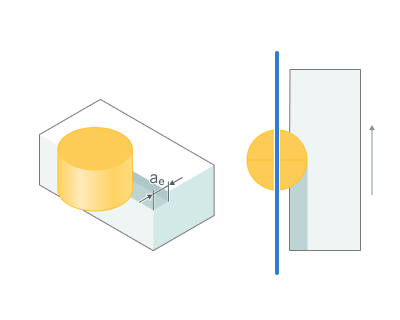

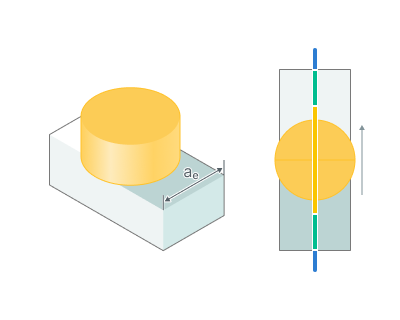

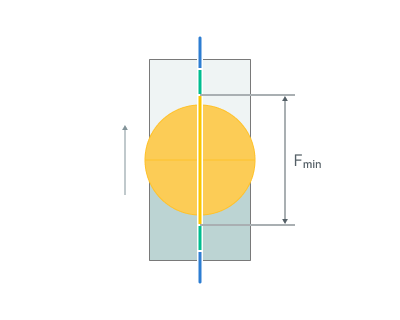

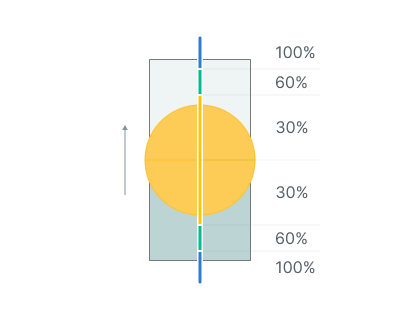

Cut Feeds:

This parameters group determines the feed rates for cutting, tool engagement, approach, and retraction. Each parameter can be specified in speed units such as mm/rev, mm/min, and for milling operations, also in mm/tooth. All speeds, except for the working feed rate, can be defined as a percentage of the working feed rate.

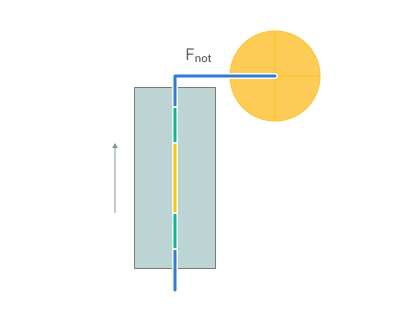

Non-cut Feeds:

This parameter group defines the speeds of auxiliary movements, including approach, return, and transitions between working passes. Each parameter can be set in speed units such as mm/rev, mm/min, and for milling operations, also in mm/tooth. Additionally, speeds can be specified as a percentage of the working feed rate or as rapid feed.

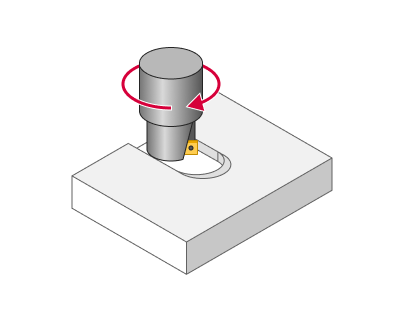

Corner control:

This group of parameters allows you to to add some specific behaviour to the toolpath corners. It is located on the bottom of "Feeds/Speeds" page. See more