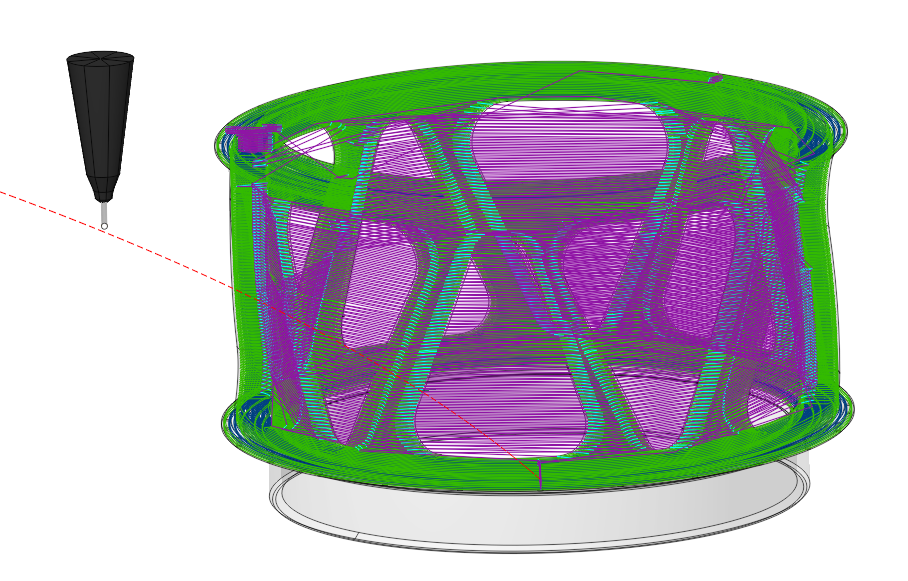

Cladding 3D operation

Application Area:

This is an additive manufacturing operation that uses a 3D model as input. It is similar to Roughing Waterline operation except that it works from the bottom to top. It intersects source model layer by layer and generates toolpath to fill calculated intersection area for each level. Operation has Parallel and Offset strategies to fill the area. By default the whole part is the model to machine. If you want to grow local geometry only then you need to add desired faces to the job assignment. System automatically fills top and bottom levels by defined geometry, but if you want to limit the upper and lower levels manually then you should select on the screen any geometrical element, lying at the desired level, and then press the "Top level" or "Bottom level" button respectively. The upper and lower levels you can set also by numerical values in the Properties inspector window.

Job Assignment:

Faces. Select various surfaces of the part that constrain the material fill area. The system will calculate the trajectory based on the chosen surfaces.

Pocket. Select the pocket bottom. The system will create the adjacent pocket walls considering the stock specified in the item Properties.. See more

Job Zone. Select the curves or edges of the part that define the material fill area. See more

Restrict Zone. In addition to Job Zones in system you can use Restrict Zones to specify the workpiece areas that have not to be machined in the current operation. See more

Top Level. Specifying the top level of material deposition by model elements. See more

Bottom Level. Specifying the bottom level of material deposition by model elements. See more

Properties. Displays the properties of an element. It is possible to add the stock. You can also call this menu by double clicking on an item in the list.

Delete. Removes an item from the list.

Strategy:

Machining Strategy.

This parameter group allows the user to achieve a required toolpath. It works similarly to the Area Cladding operation. See more.

Machining levels:

It defines the range along tool axis for the machining. This parameter group works similarly to the Area Cladding operation. See more.

Trimming:

Allows for the skipping of surfaces not intended for machining and allows for the extension of the toolpath. The parameters of Trimming are the same as in the Waterline Roughing operation. See more.

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more.

See also: