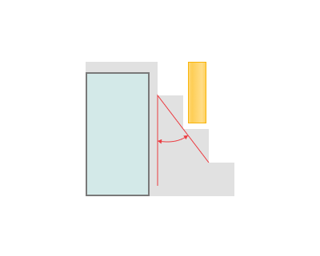

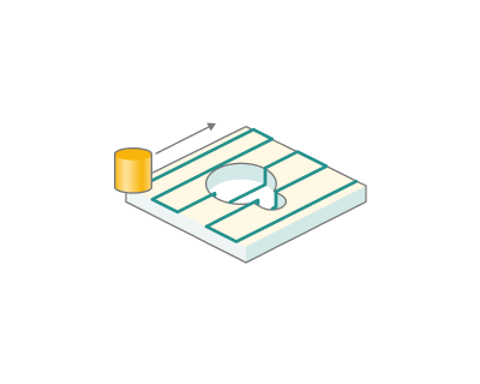

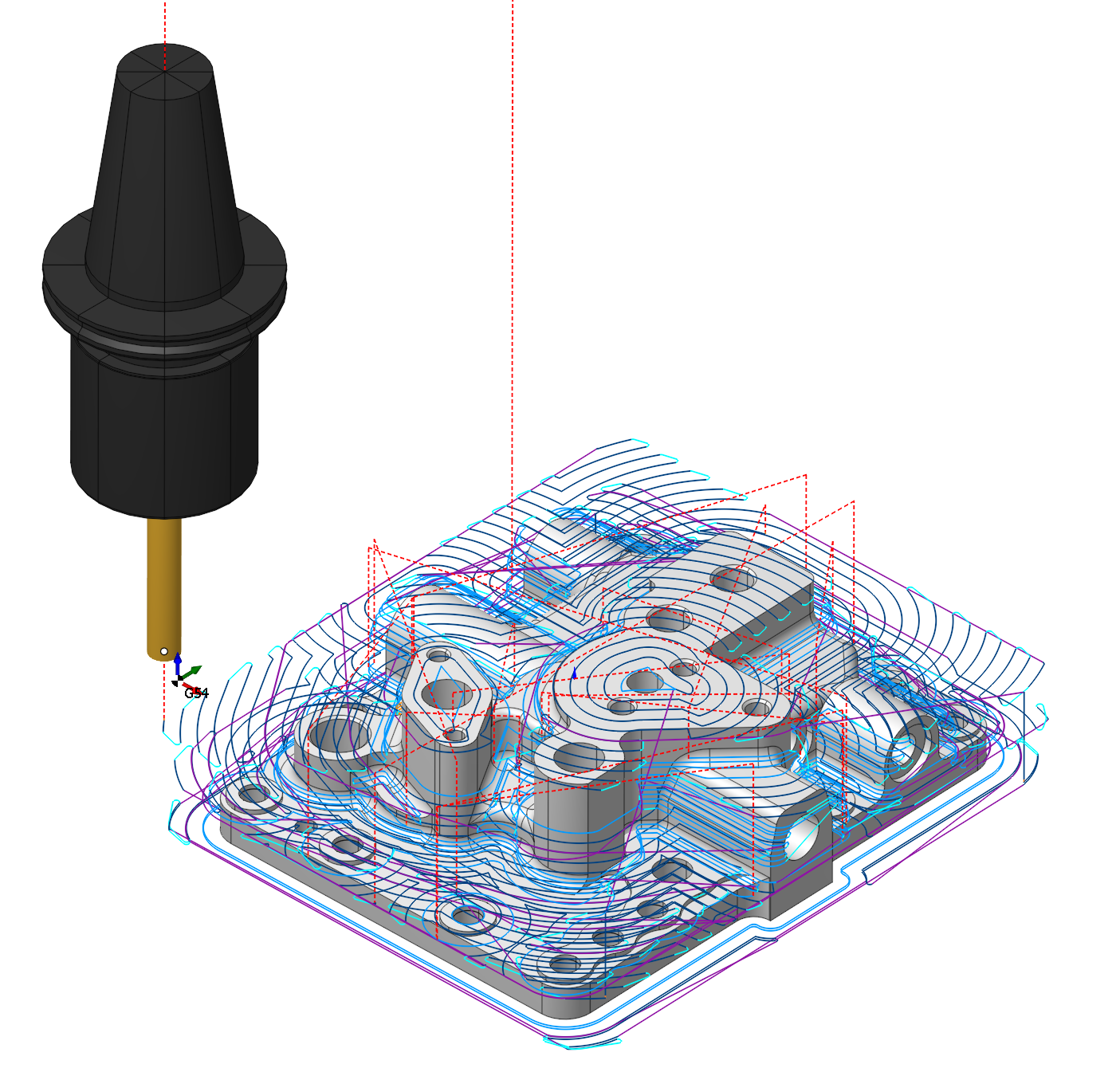

Waterline roughing operation

Application area:

The waterline roughing operation is used for the initial rough machining of complex-shaped models that differ significantly from the original workpiece. A model being machined by the waterline roughing operation is assigned by a set of solid bodies, surfaces and mesh objects. For every geometrical object or a group of objects, an additional stock, which during machining will be added to the main stock of the operation, can be defined.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Job assignment:

Faces. Select various surfaces of the part as the working task. The system will calculate the trajectory based on the chosen surfaces.

Pocket. A typical prismatic or turn-milling part consists of many simple shapes.To simplify this task, we can recognize the parts elements in a 3d model and automatically convert them to basic job assignment items, such as job zones and machining levels. See more

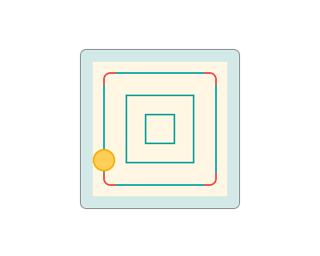

Job Zone. Job zones are used to define the part areas that have to be machined by roughing and finishing milling operations. See more

Restrict Zone. In addition to Job Zones in system you can use Restrict Zones to specify the workpiece areas that have not to be machined in the current operation. See more

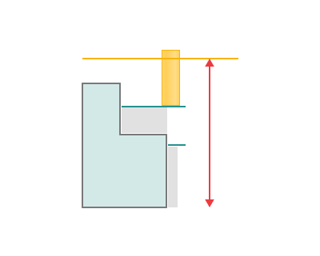

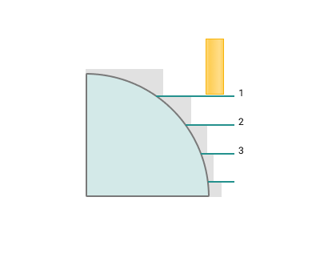

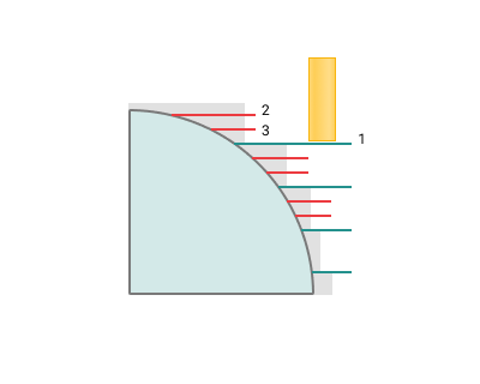

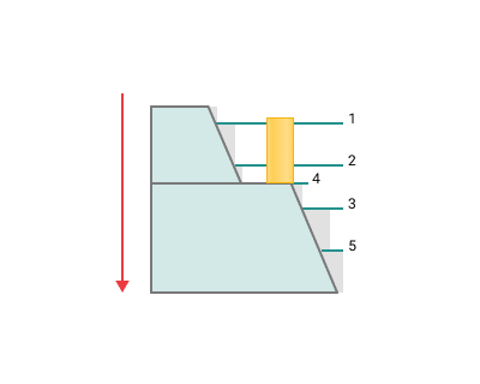

Top Level. Specifying the top level by model elements. See more

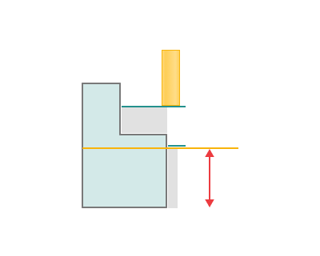

Bottom Level. Specifying the bottom level by model elements. See more

Properties. Displays the properties of an element. It is possible to add the stock. You can also call this menu by double clicking on an item in the list.

Delete. Removes an item from the list.

Strategy:

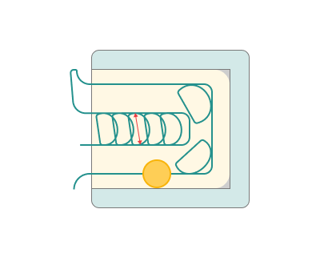

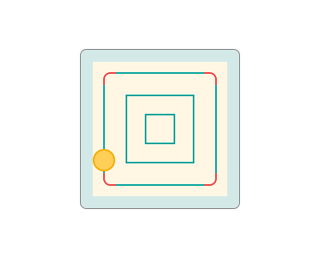

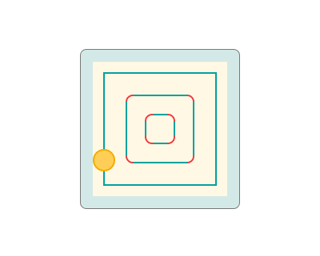

Machining strategy:

This parameter allows the user to achieve a toolpath that appears parallel or equidistant or other when performing pocketing operations.

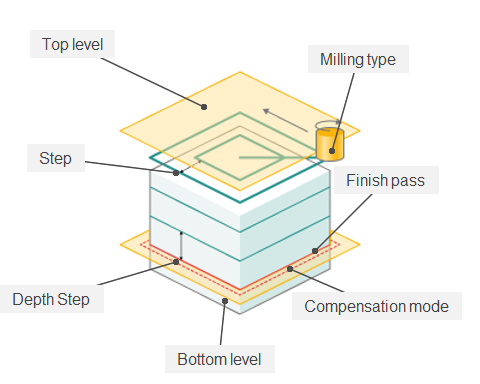

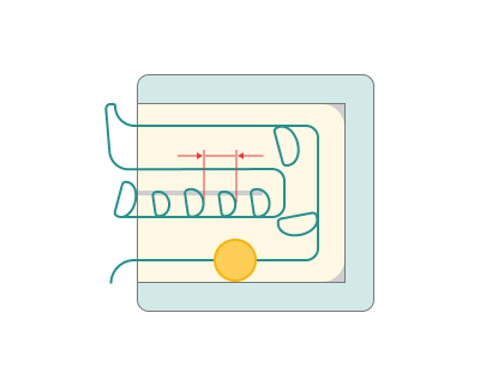

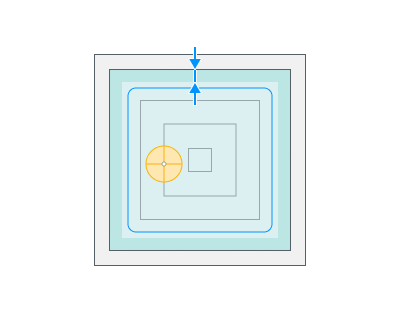

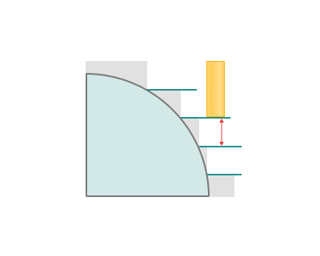

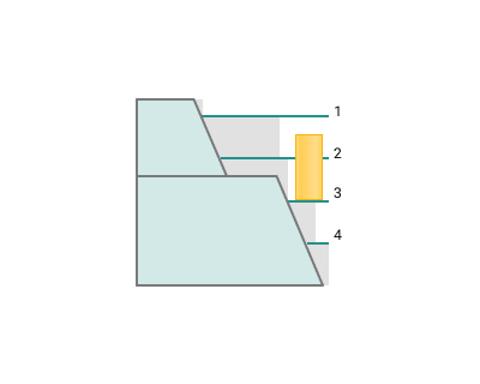

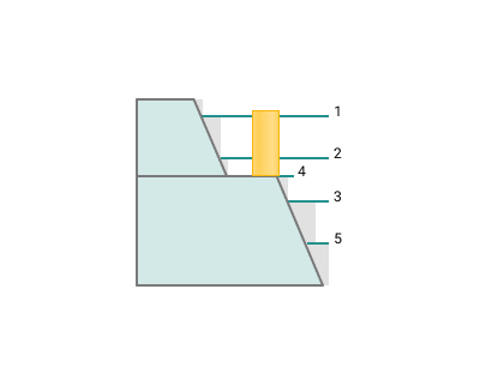

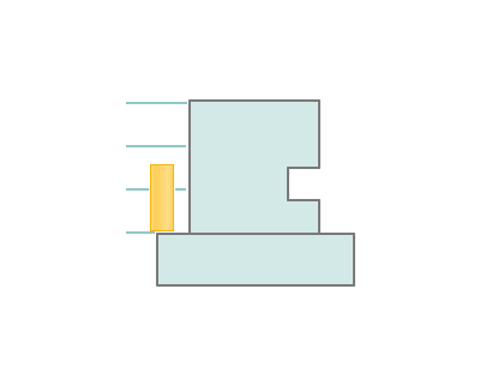

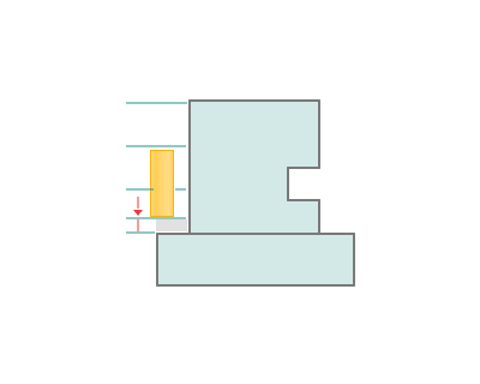

Machining levels:

It defines the range along tool axis for the machining.

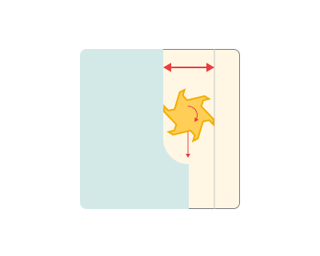

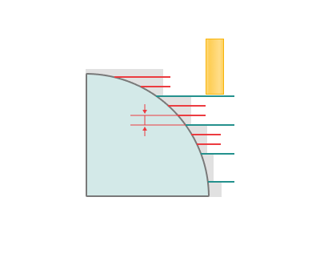

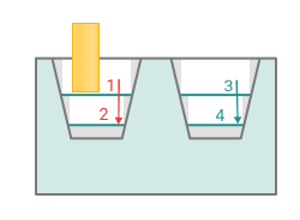

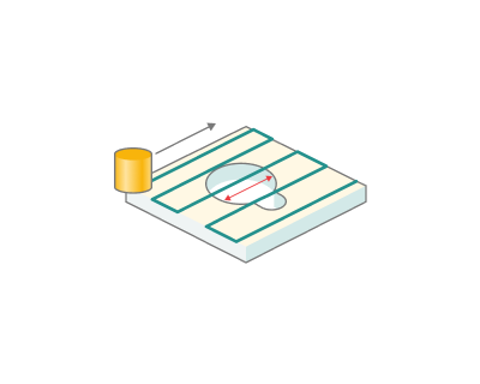

Depth Step:

Material removed in one pass along the tool axis between the Top and Bottom levels.

Here are the key parameters, the set of which may vary depending on the chosen strategy in the Machining strategy section:

Clear flats.

Extra passes are applied for flat faces.

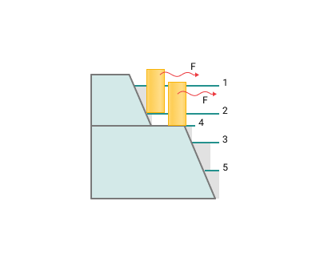

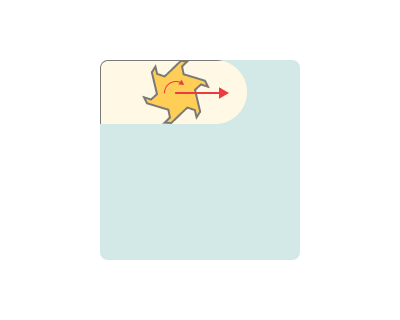

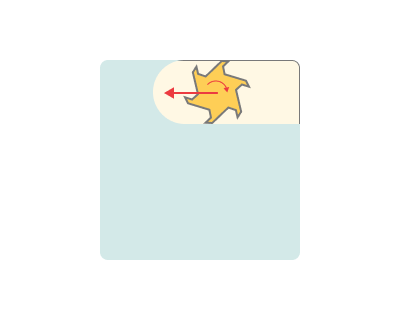

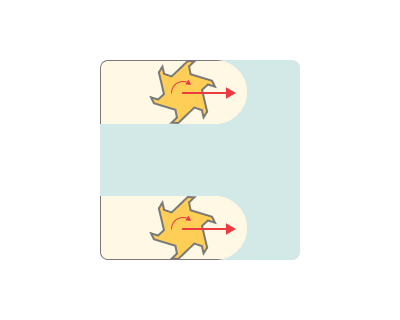

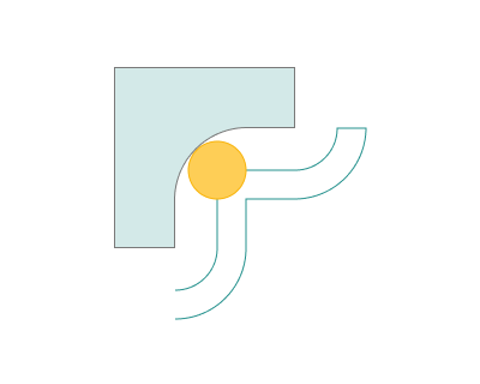

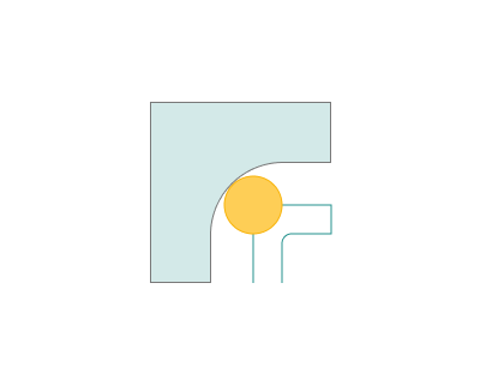

Milling type:

Сan be assigned in almost all operations, except for the curve machining operations. This allows the user to control the required milling type (climb or conventional) during the toolpath calculation process.

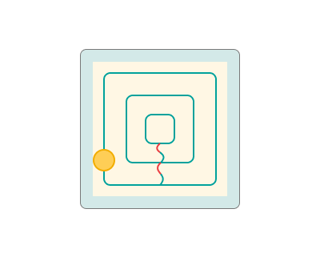

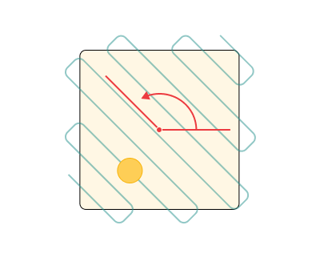

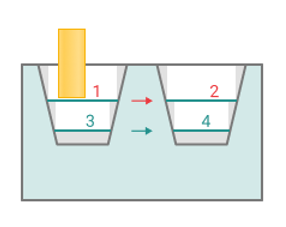

Sorting.

Controls the sequence of toolpath passes during the surface machining .

Trimming

Allows for the skipping of surfaces not intended for machining and allows for the extension or trimming of the toolpath .

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more