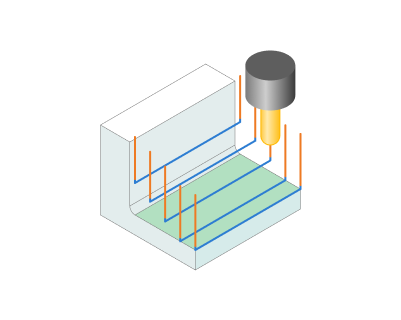

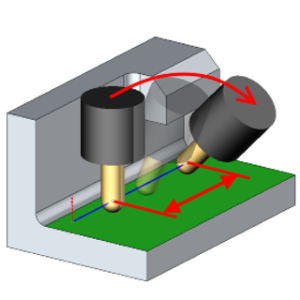

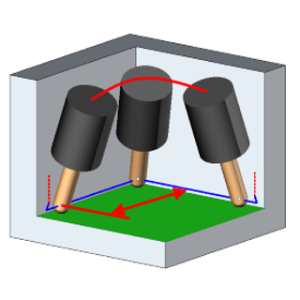

5D Meshing operation

Application Area:

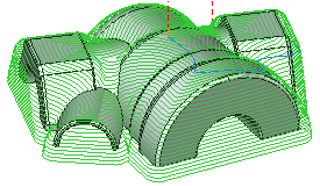

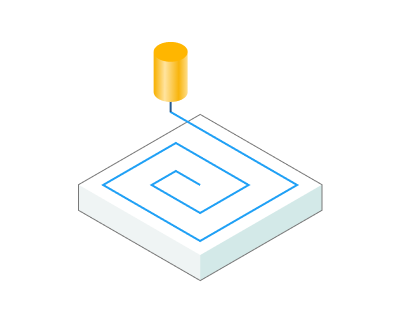

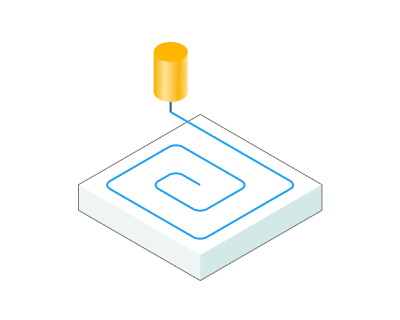

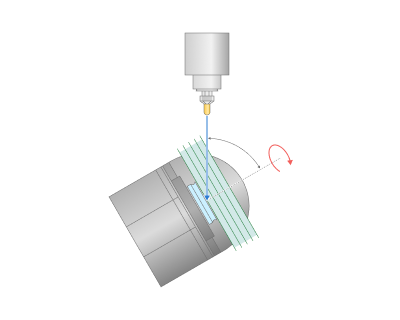

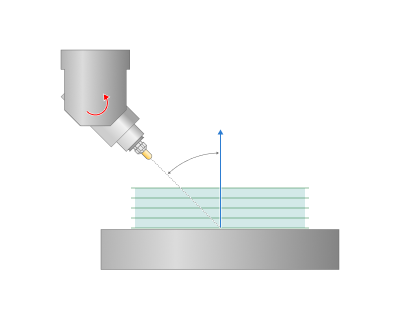

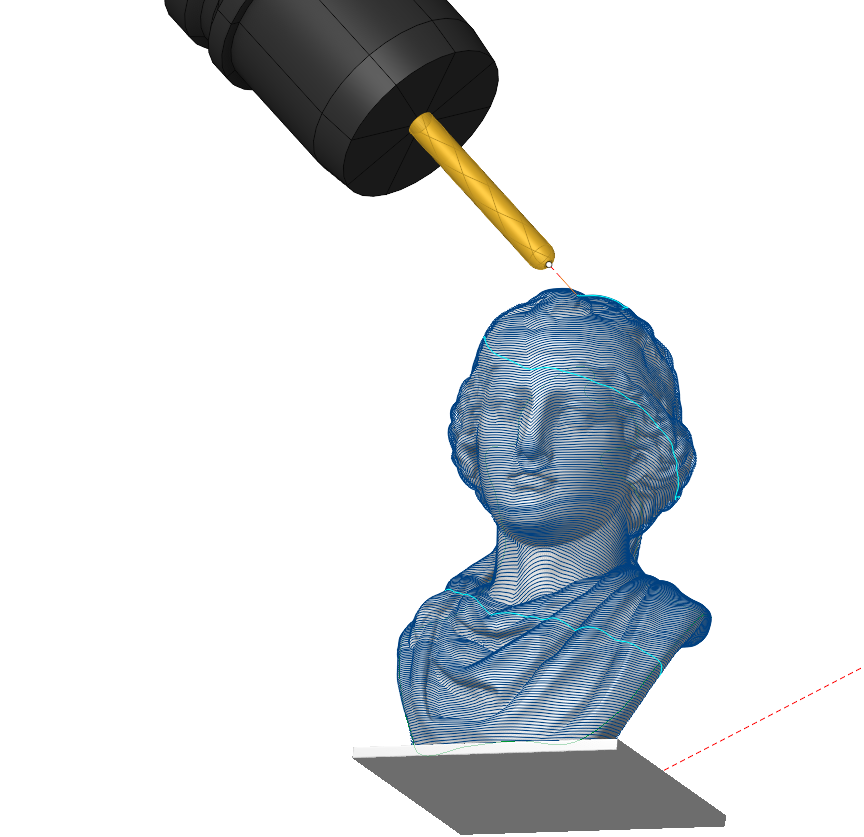

A versatile 5 axis finishing operation with a powerful set of strategies, tool axis orientation modes and automatic tool and holder collision avoidance. Perfect for finishing of complex shapes such as sculptures or scanned STL models. Easy to use. The operation allows machining mesh models similarly to Scallop finishing operation, 3D Helical operation and Waterline strategy from 5D Surfacing operation. The operation allows generating machining toolpath on the 5 axis machines and robots. The operation supports surface models and triangular mesh models. You can use spherical, conical mills with a spherical end and lollipop mills.

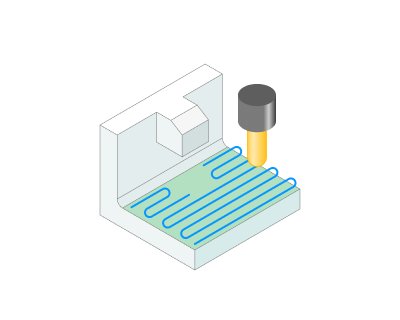

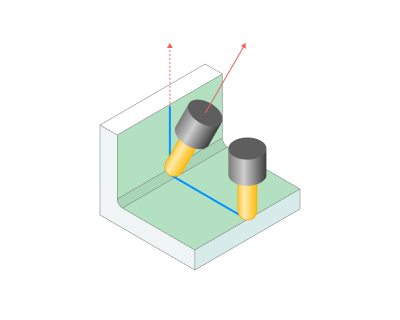

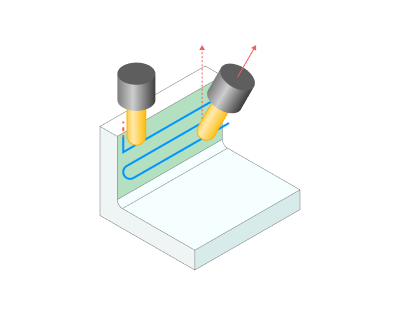

To start machining just create the operation and press Run. The operation will generate a scallop pattern on the whole part starting from the bottom level. The tool will stay in the vertical orientation unless there is a collision with the part, otherwise it will be tilted to the side.

Workflow:

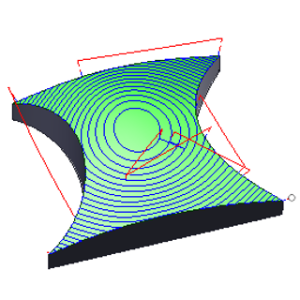

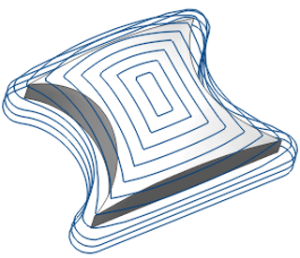

Define the toolpath Strategy. The default strategy is Scallop as it allows to machine the whole part with a consistent stepover.

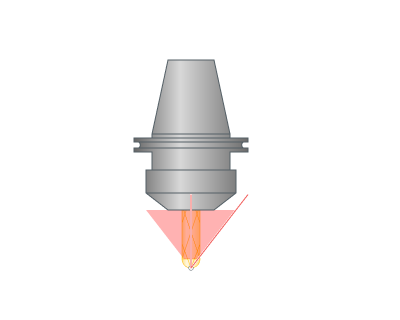

Choose the tool axis orientation. The default option is Fixed, because together with the automatic collision avoidance it doesn't require any additional setup and achieves a smooth and predictable toolpath.

Define the collision avoidance strategy. The default is Side Tilting, as it is works well with Scallop, Helical and Waterline patterns.

Optionally, define the job zone

Generate the toolpath

Job assignment

Machining Surfaces. Select various surfaces of the part as the working task. The system will calculate the trajectory based on the chosen surfaces.

Tilt Curve.

This is t

he curve that the tool axis vector aims at when setting

Tool Orientation

specification

Through Curve.

Job Zone. Use the Job Zone to trim the passes outside the specified 2D containment areas. You can select the normal to the area of Job Zone. See more .

Restrict Zone. In addition to Job Zones in system you can use Restrict Zones geometry from curves and edges to specify the workpiece areas that s hould avoid machining in the current operation. See more

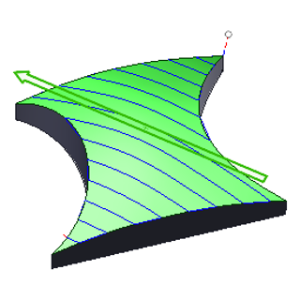

Start Curves. Using a closed curve, such as a spline, you can select a model segment for machining. You can specify the machining side and configure vectors to define the tool axis orientation.

Properties. Displays the properties of an element. It is possible to add the stock. You can also call this menu by double clicking on an item in the list.

Delete. Removes an item from the list.

Strategy:

Strategies:

This parameter allows the user to achieve a required toolpath:

Start From:

This group of parameters appears when the Scallop strategy is active and determines the construction of the initial toolpath curves.

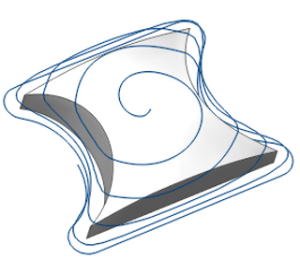

Smooth Radius:

This parameter appears when the Helical strategy is active and a llows for the smoothing of inner toolpath corners using a designated radius.

Job zone:

Enables additional modification of the working area initially selected on the Job assignment tab.

Milling Type:

Сan be assigned in almost all operations, except for the curve machining operations. This allows the user to control the required milling type (climb or conventional) during the toolpath calculation process.. See more

The parameters of the Milling Type are the same. as in the Waterline Roughing operation. See more.

Sorting.

Controls the sequence of toolpath passes during the surface machining .

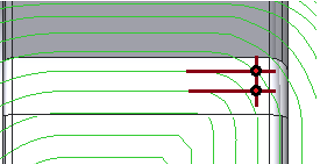

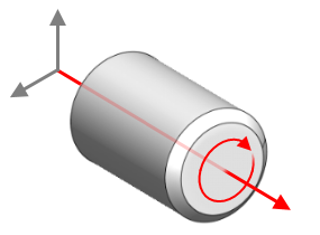

Tool Orientation:

Controls tool axis orientation. The principal parameters of this function are the same as in the 5D Surfacing operation. See more.

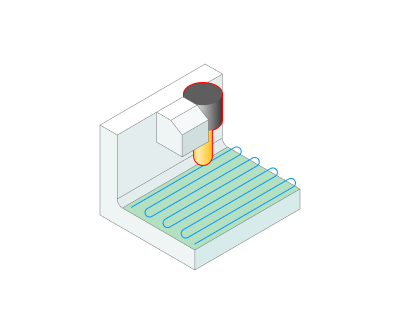

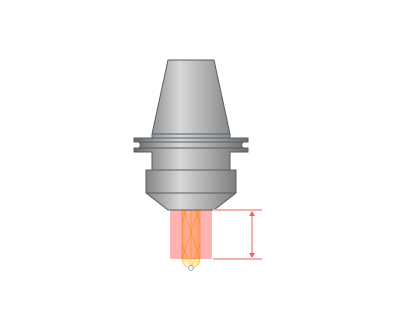

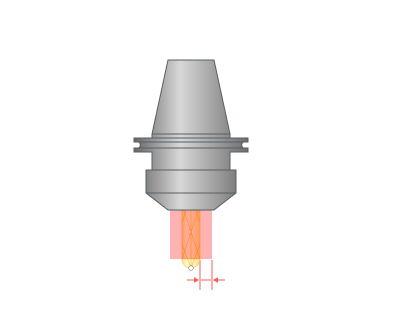

Avoid Collisions:

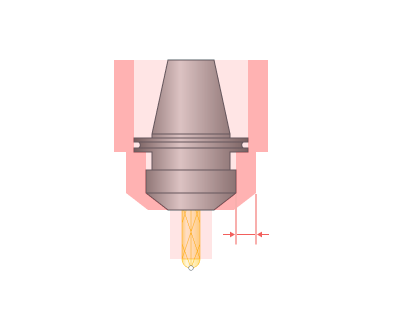

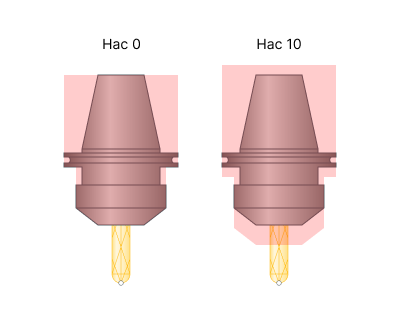

With the Check Holder function, this feature detects segments of the toolpath where the tool holder collides with the part and modifies those segments according with the specified strategy.

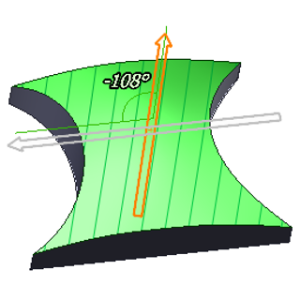

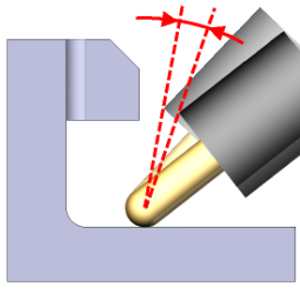

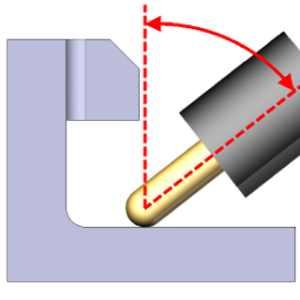

Limit Rotation Angles:

This option specifies the limit values of the tool's angular position relative to the axes. The parameters of Limit Rotation Angles are the same as in the 5D Surfacing operation. See more.

Trimming:

Allows for the skipping of surfaces not intended for machining and allows for the extension of the toolpath . The parameters of Trimming are the same as in the Waterline Roughing operation . See more.

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more