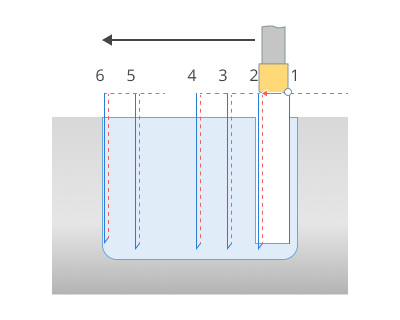

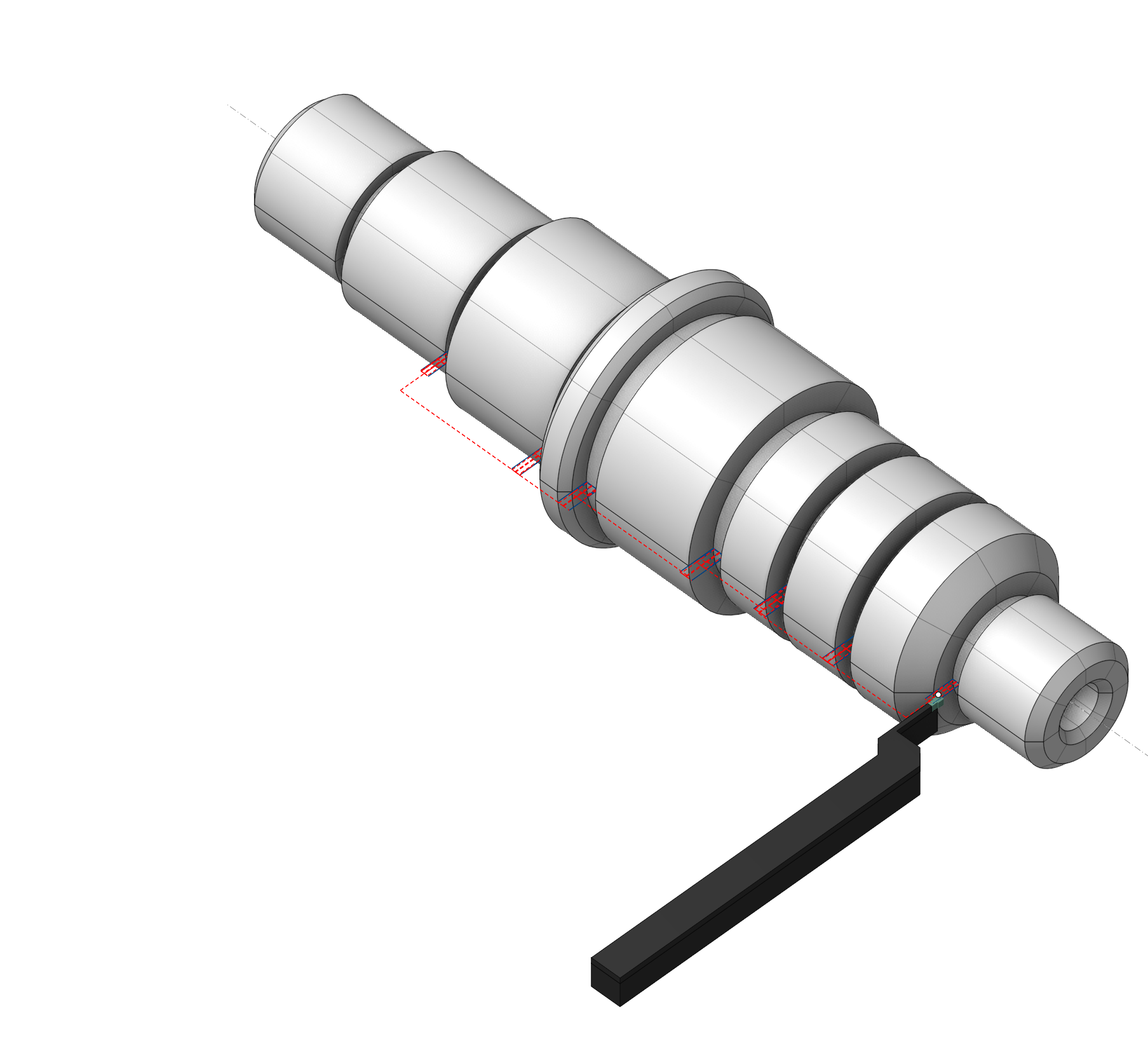

OD Grooving, ID Grooving and Face grooving operations

Application area:

This operation turns grooves or closed areas that are inaccessible for processing by other types of turning operations. Rough machining consists of a sequence of passes perpendicular to the axis of the part. Finish passes are the movements that closely follow the contour of the part.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Job assignment:

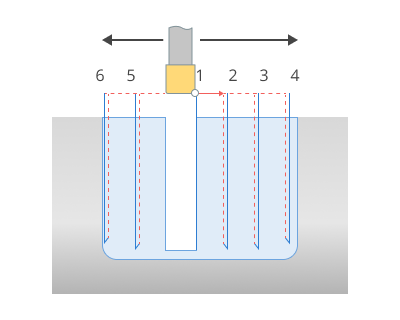

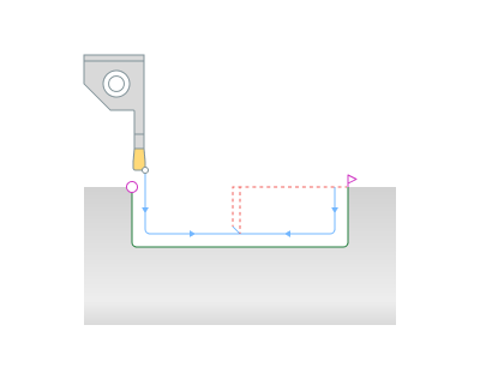

Slotting. This cycle efficiently machines simple rectangular grooves with a minimum number of actions. See more

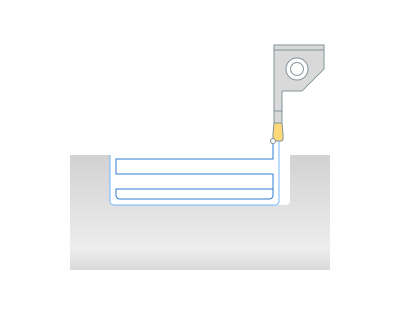

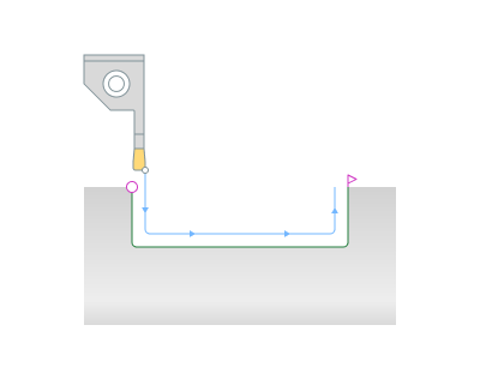

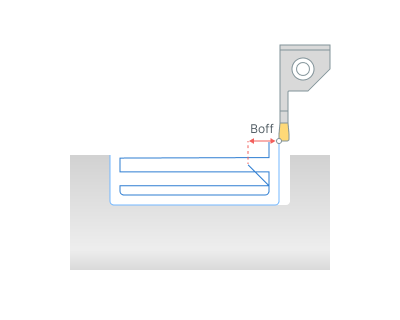

Grooving . This cycle creates a complex toolpath for turning all types of grooves and undercuts. The cycle identifies the lowest point of the groove and processes both its sides with different cutting edges of the tool. See more

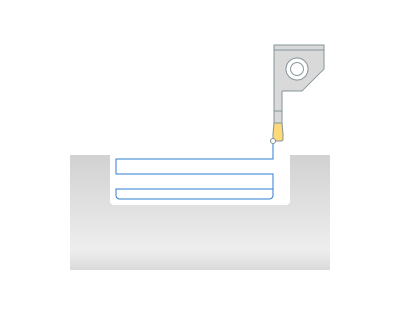

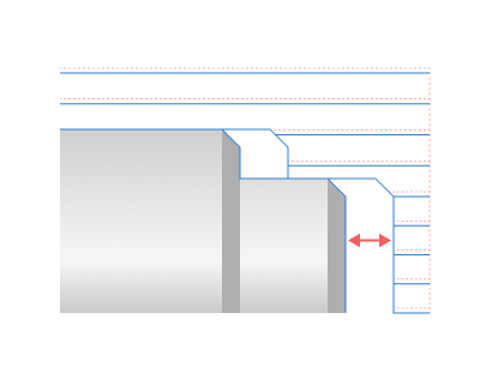

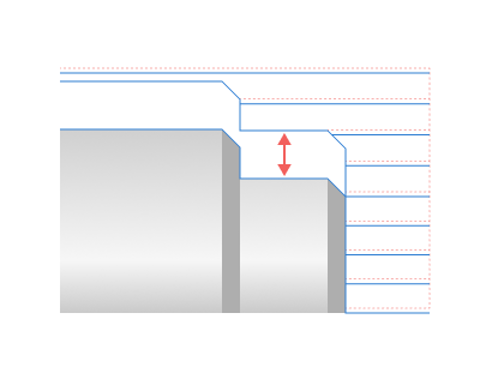

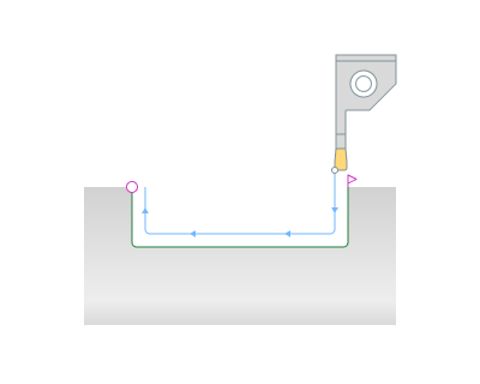

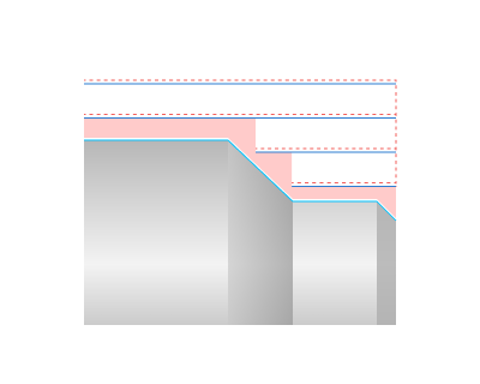

Zigzag. The tool removes the rough stock layer by layer. In each layer, it plunges downwards to the cutting depth and performs horizontal movement. Thus, horizontal passes with alternating directions remove the entire rough stock, layer by layer. See more

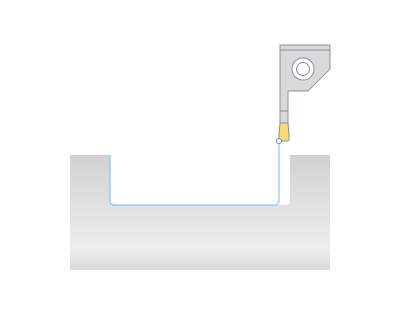

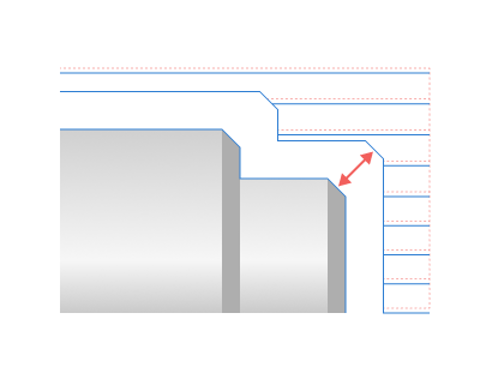

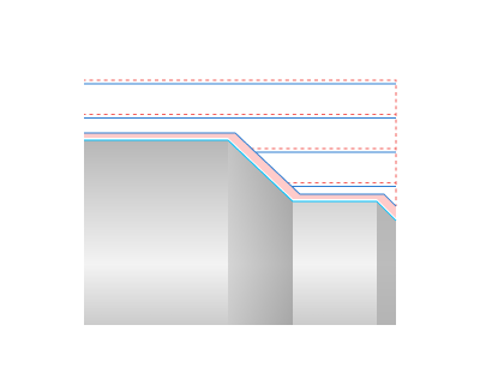

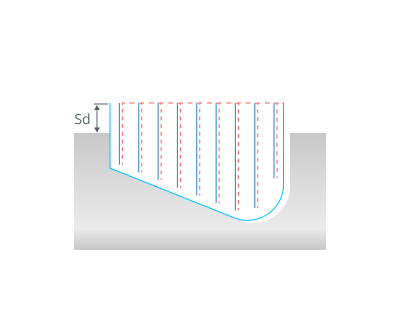

Profile. The system forms a single pass, the toolpath of which is identical to the geometric contour of the part. User can add engage/retract; shifting by stock values; tool unreachable gray zones excluding; tool radius compensating to the toolpath. See more

Properties. Displays the properties of the selected element. You can additionally add allowance. You can call the Properties menu by double-clicking on the selected element.

Delete. Removes the selected item from the list.

Restrictions. It allows you to restrict areas that should not be machined. See more

Cycle parameters:

Cycle:

You can select one of the available turning cycles described in the Job assignment. When you switch a cycle in this section, the corresponding element in the Job assignment automatically changes. The set of parameters varies for each turning cycle.

Roll by arcs.

The system rounds the external corners of the toolpath by arcs with a radius equal to the tool nose radius. The parameters group works similarly to the OD Roughing and ID Roughing operations. See more

Feeds/Speeds:

Using this dialogue the user can define the spindle rotation speed; the rapid feed value and the feed values for different areas of the toolpath. Spindle rotation speed can be defined as either the rotations per minute or the cutting speed. The defining value will be underlined. The second value will be recalculated relative to the defining value, with regard to the tool diameter. See more

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more

Part:

A Part is a group of geometrical elements that defines the space to check for gouges. See more

Workpiece:

A workpiece model of an operation defines the material to be machined. See more

Fixtures:

As the Fixtures the fixing aids such as chucks, grips, clamps, etc., and the restriction areas of any other nature are usually specified. See more

See also: