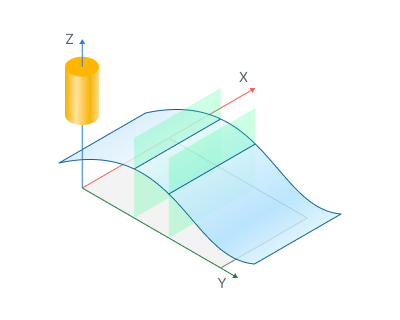

Non-planar slicing

Application area:

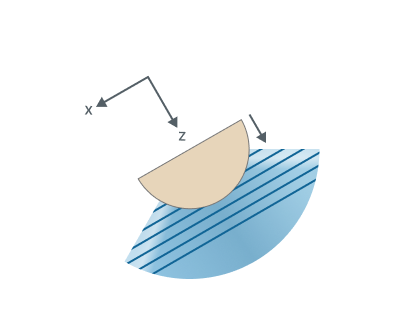

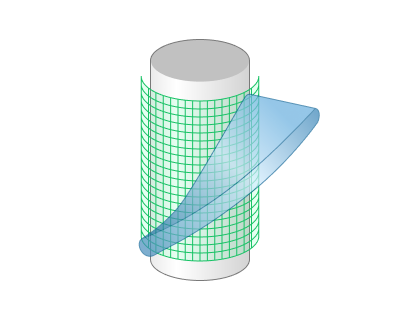

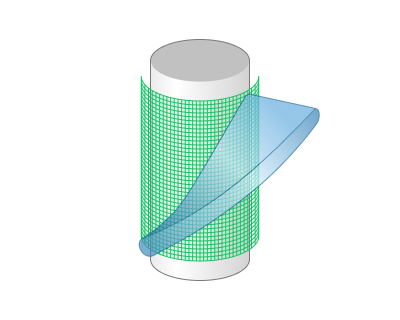

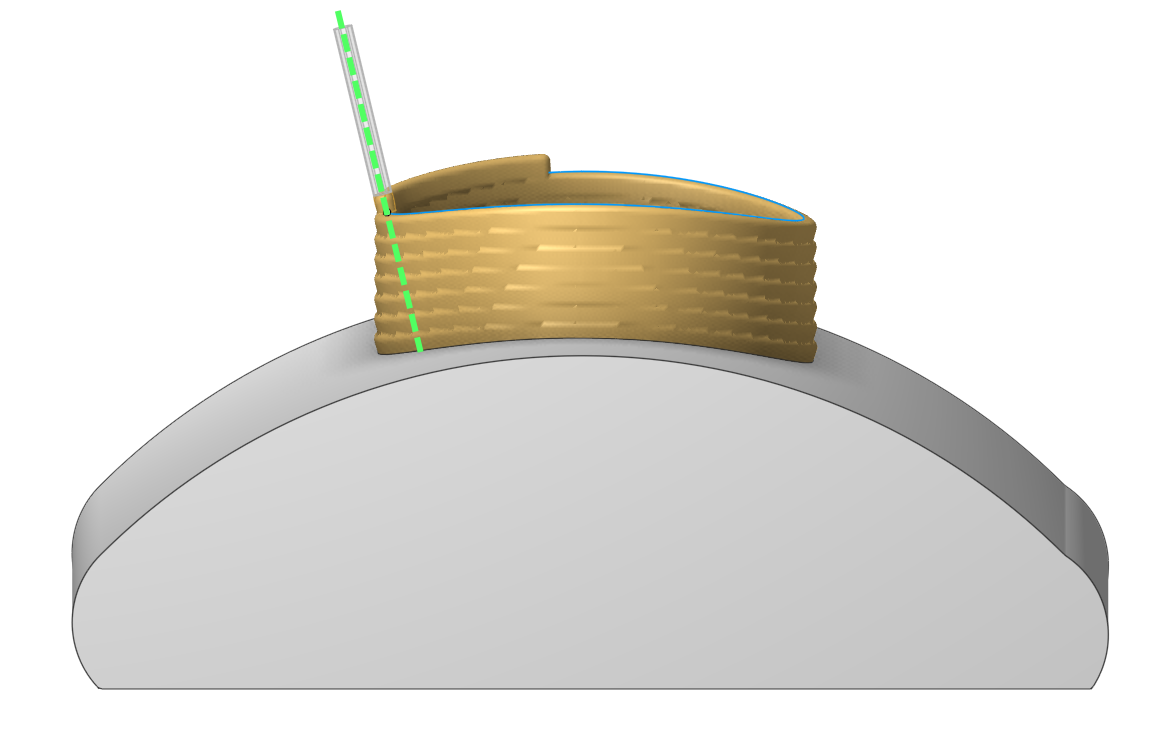

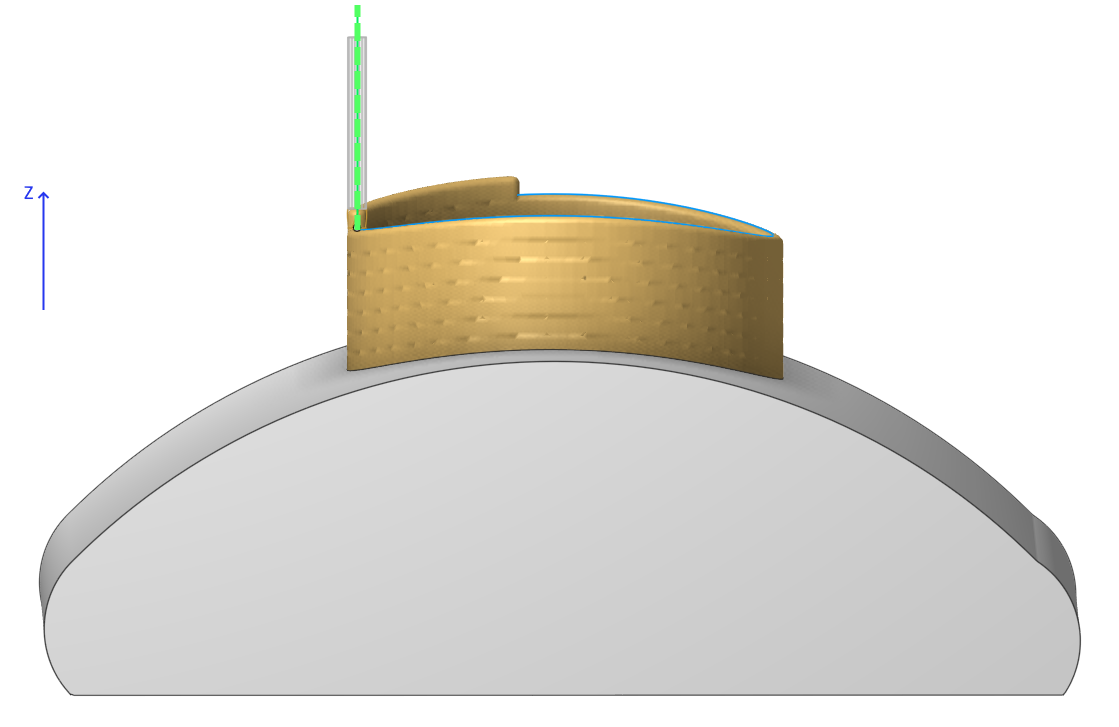

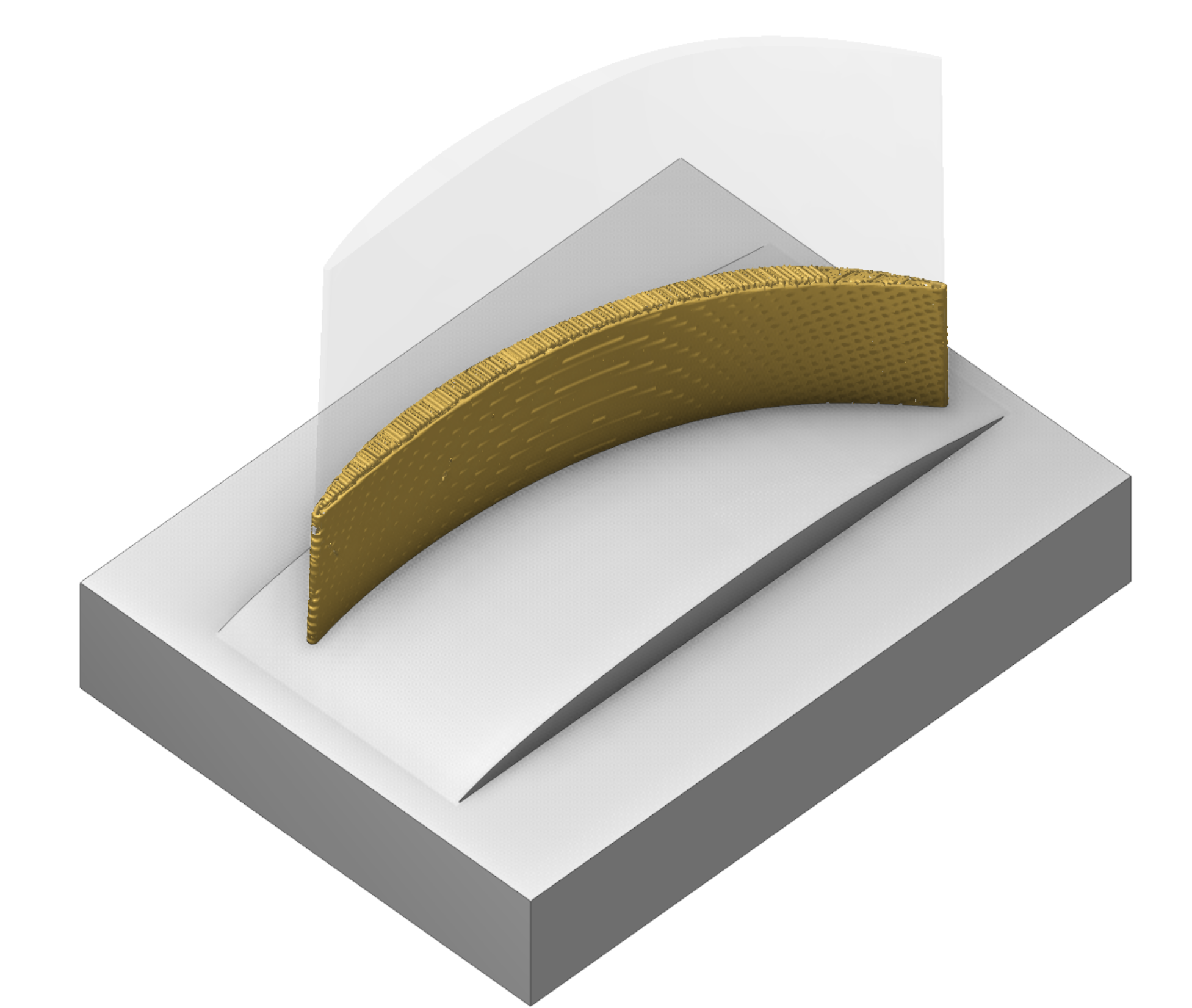

This operation allows you to print models on arbitrary substrates. It uses a non-planar slicer engine and generates a non-planar additive printing path. But also it's possible to generate a classic planar printing path with some extra parameters.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Job assignment:

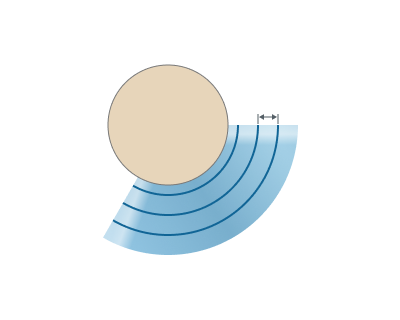

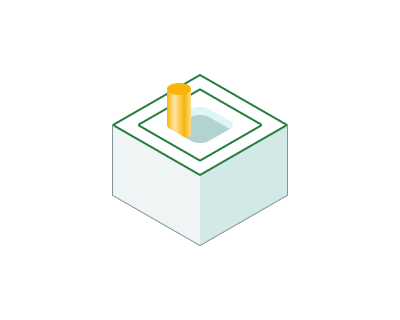

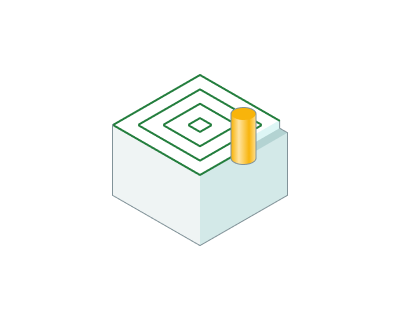

Non-planar substrate. Substrate for printing (for "Offset" strategy only)

Feature. Desired model, that should be printed

Properties. Disabled

Delete. Removes an item from the list

Strategy:

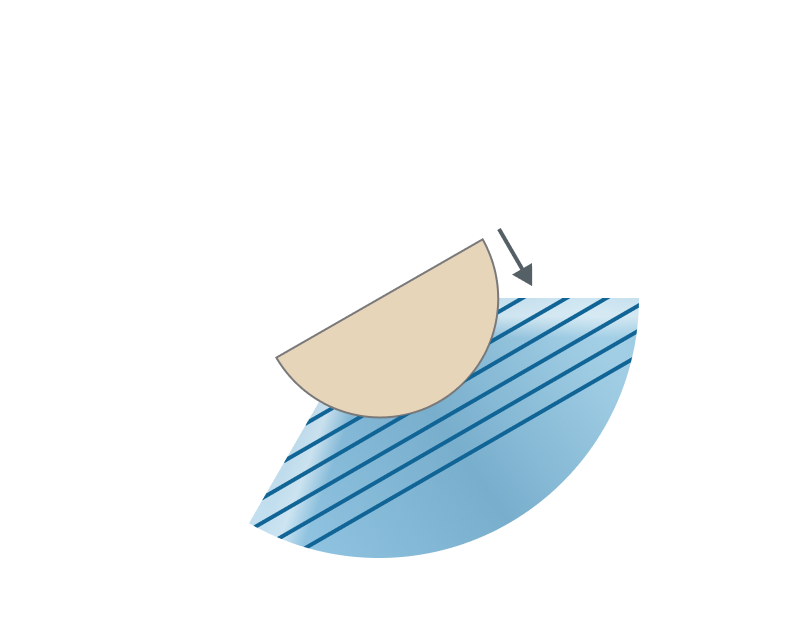

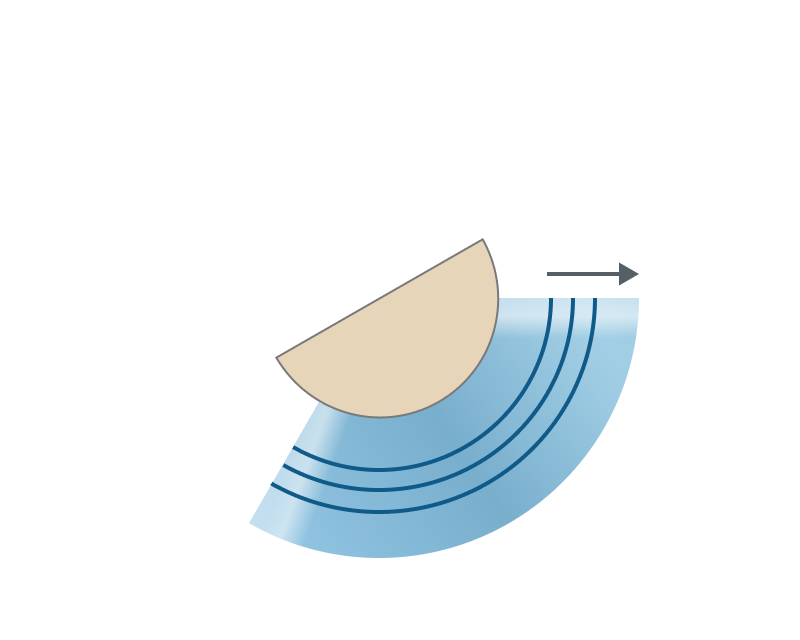

Slicing strategy.

Defines the slicing strategy.

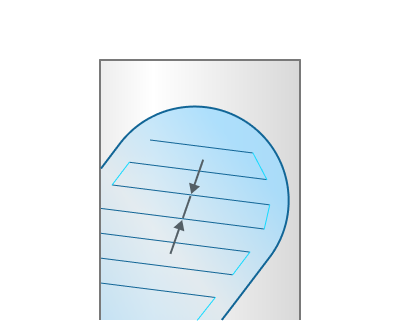

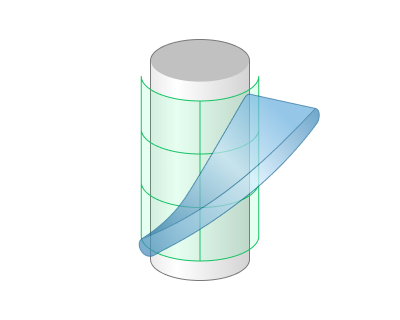

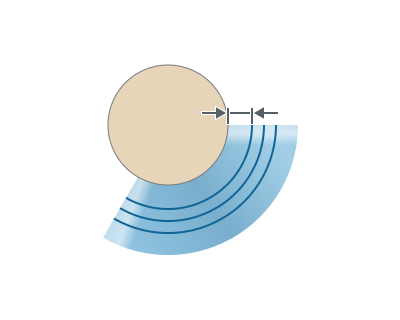

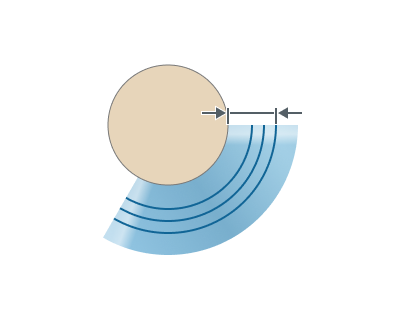

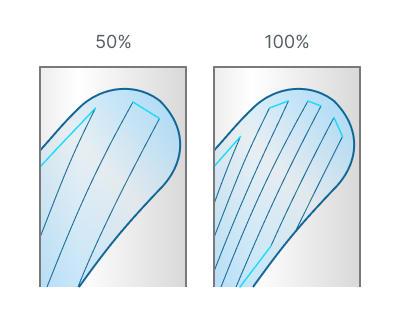

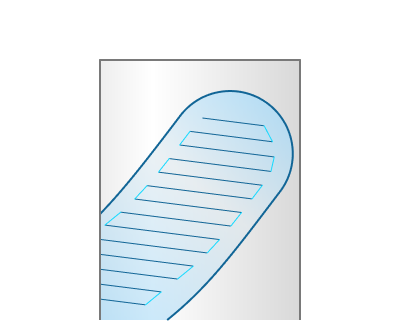

Print inner volume.

Offsets the tool path into the model by half of the line width value

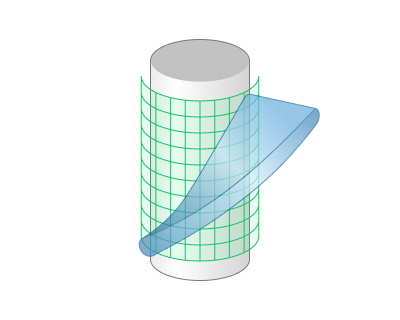

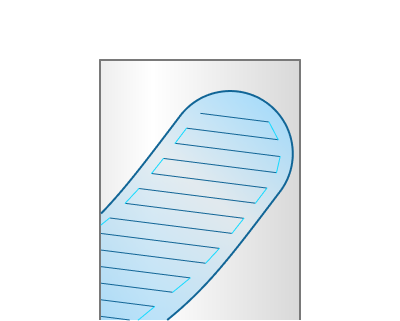

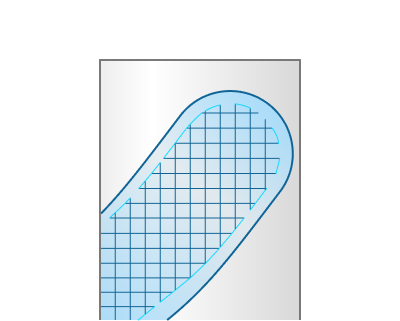

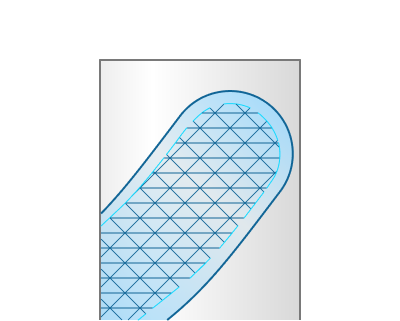

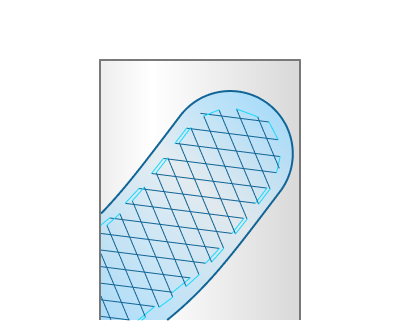

Infill.

A group of parameters to generate an infill for the model.

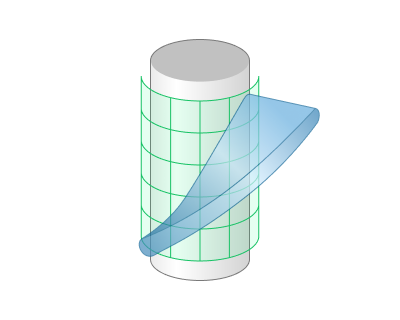

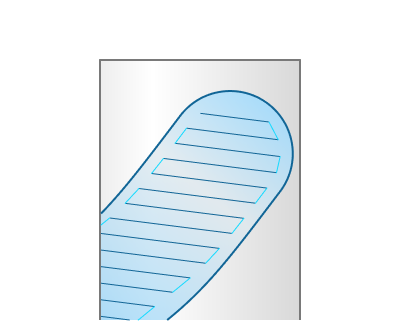

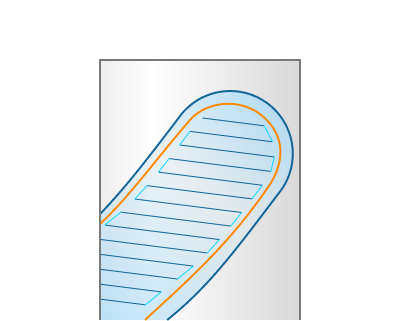

Double walls.

Adds an additional inner wall.

Sorting.

Toolpath sorting and linking parameters.

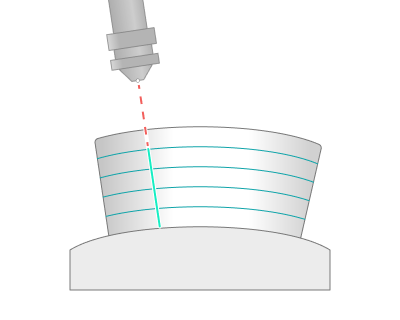

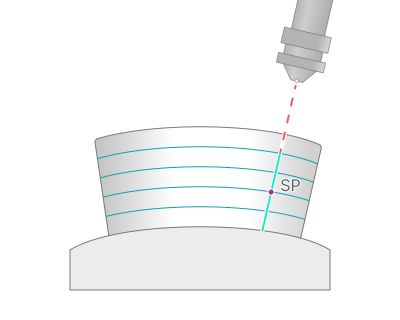

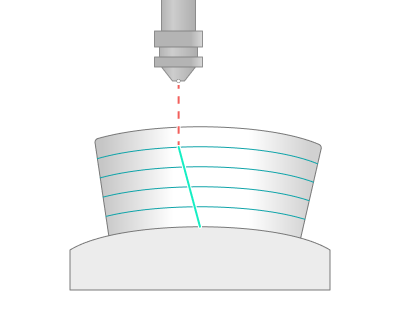

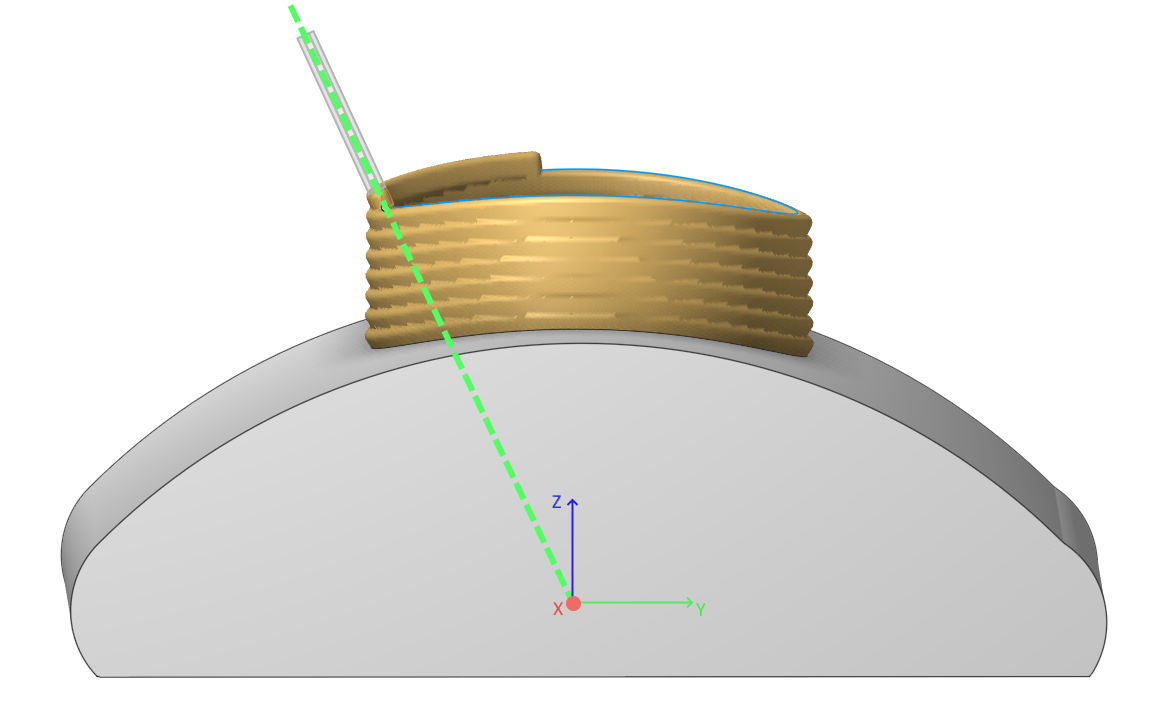

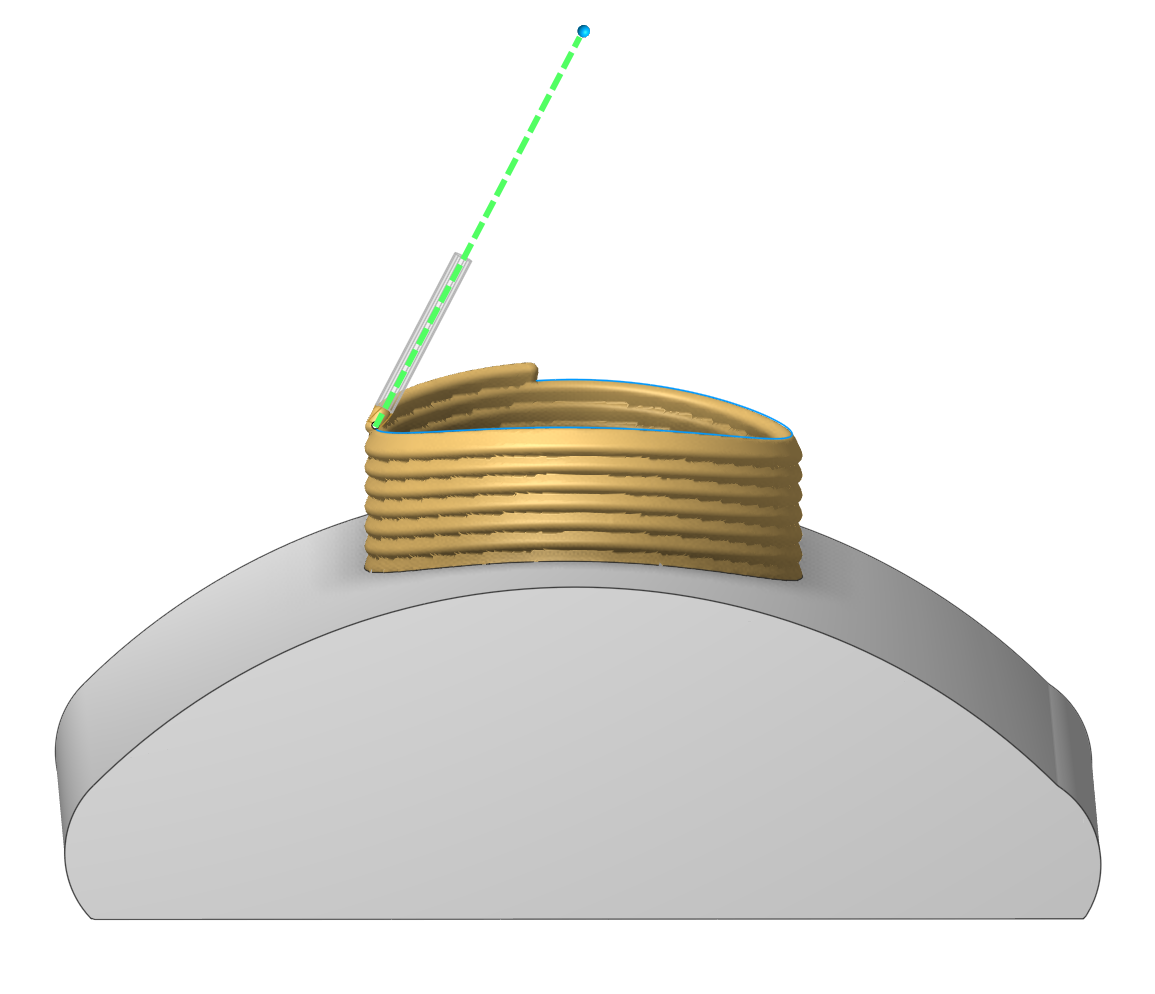

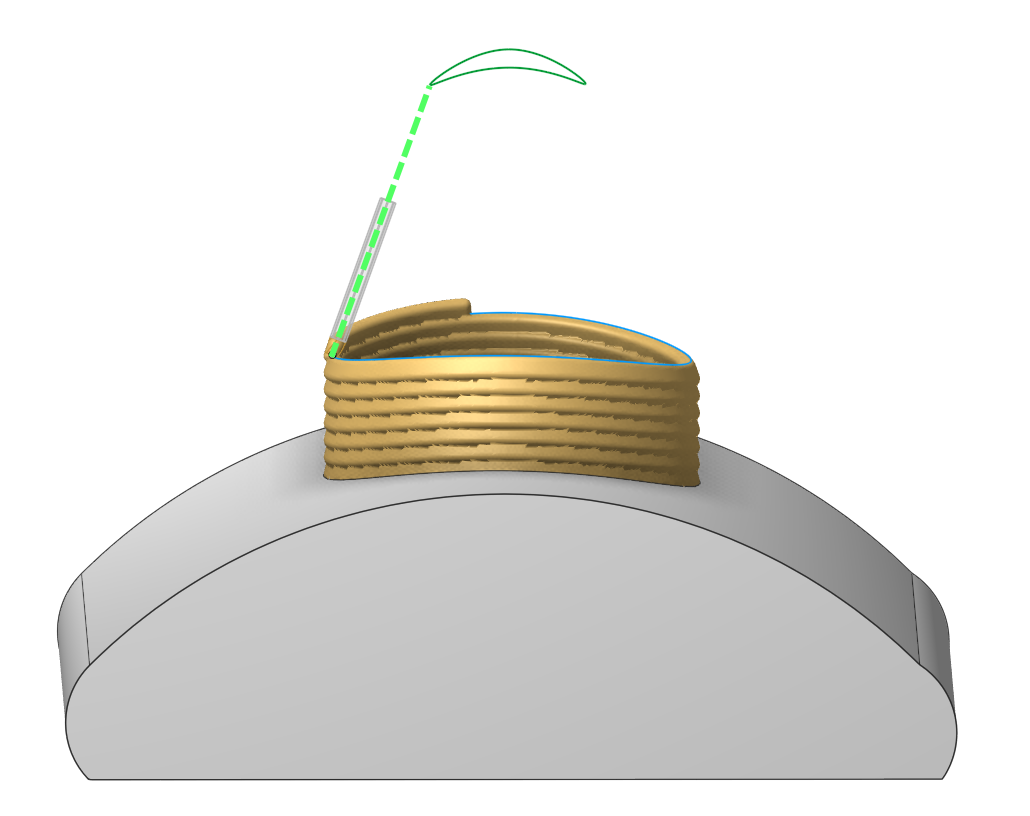

Tool orientation.

This parameter allows you to set different tool orientation (normal) without changing the original toolpath. There are five options avalaible for users: "Normal to surface", "Fixed", "To rotary axis", "Through point" and "Through curve".

Limit rotation angles.

When the flag is set, it specifies the limit values of the tool's angular position relative to the specified axis. This parameter group works similarly to the " 5D Surfacing" operation . See more.

Parameters:

Output Interpolation.

Using interpolation is one of the main ways to modify the path, allowing you to adjust smoothness and the concentration of points on trajectory. See more.

Minimum Layer Time.

This parameter allows you to set the minimum allowed time in seconds for printing a single layer. See more.

Simulation.

Determine the parameters for the simulation output settings. See more.

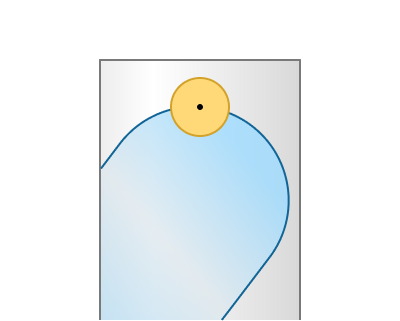

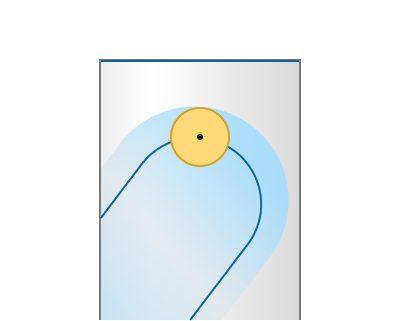

Links/Leads:

In the Links/Leads tab, you define the parameters for rapid movements. These movements include tool approach from the tool change position, engage to the start of the working stroke, retraction after the final cutting motion, transitions between working passes, and return to the tool change point. You can configure the sequence of movements along the coordinates, the trajectory of these motions, and the magnitude of displacements.

Feeds/Speeds:

Using this dialogue the user can define the rapid feed value and the feed values for different areas of the toolpath. Also it's possible to apply "Corner control" parameters on this page. See more

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more

Important note

The "Multiply scheme" parameter in this operation behaves differently compared to other operations.

Normally, this parameter duplicates the entire toolpath of the operation - including the slicing results and the links/leads between layers.

However, in this operation, it only duplicates the slicing result before the linking stage.

This allows to multiply features and apply settings like "Links/Leads" or "Split by Layers", which would not be possible using the standard multiplying method.

Part:

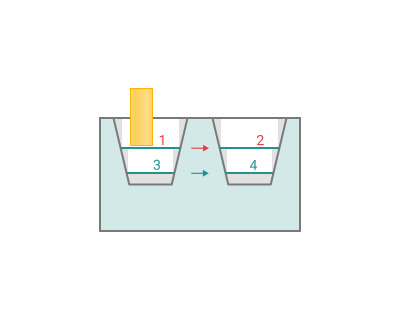

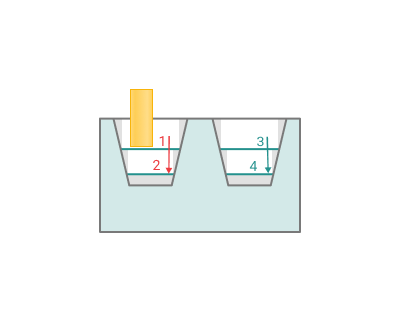

A Part in additive manufacturing is a desired geometry to be manufactured by the printing process . See more

Workpiece:

A Workpiece in additive manufacturing is t he pre-existing material or substrate that serves as the foundation for printing (can be empty) . See more

Fixtures:

As the Fixtures the fixing aids such as chucks, grips, clamps, etc., and the restriction areas of any other nature are usually specified. See more