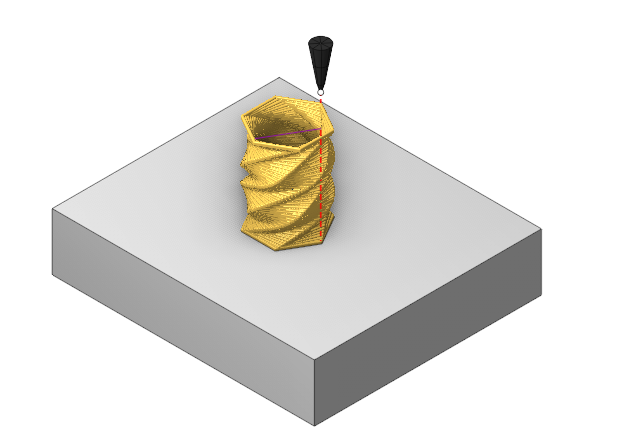

Direct cladding

Application area:

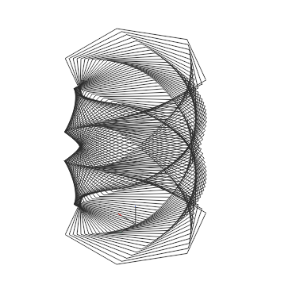

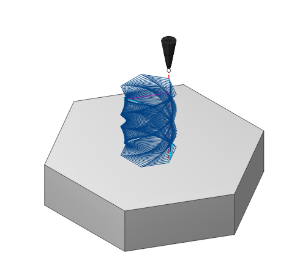

The operation lets you do surfacing along curves you’ve set up beforehand. You can prepare the curves using any tool — for example, a third‑party CAD program. Basically, the operation turns a bunch of curves into a path for the tool to follow. It also automatically sorts and divides the work area into regions. You can choose between layer‑by‑layer and spiral processing modes.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Job assignment:

Curve. Set the toolpath along the selected curve . See more.

Properties. Displays the properties of an element. It is possible to add the stock. You can also call this menu by double clicking on an item in the list.

Delete. Removes an item from the list

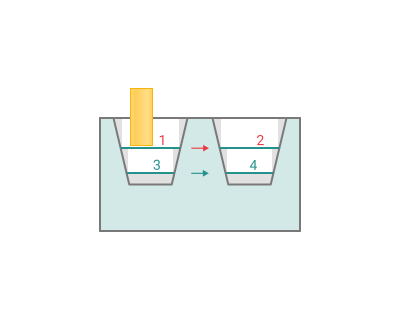

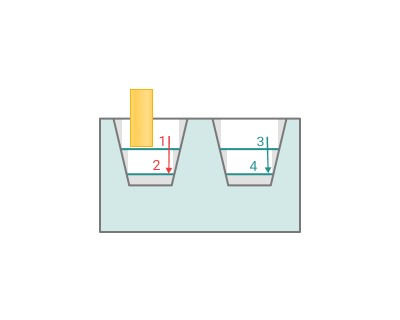

Strategy:

Printing strategy.

The choice of strategy affects the availability of parameters in the Sorting group.

Sorting.

Toolpath sorting and linking parameters.

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more

Part:

A Part is a group of geometrical elements that defines the space to check for gouges. See more

Workpiece:

A workpiece model of an operation defines the material to be machined. See more

Fixtures:

As the Fixtures the fixing aids such as chucks, grips, clamps, etc., and the restriction areas of any other nature are usually specified. See more

Download:

Select the latest version and download the " DirectCladdingOperationExtension.dext" from the Assets section.

https://github.com/EncySoftware/DirectCladdingOperation/releases