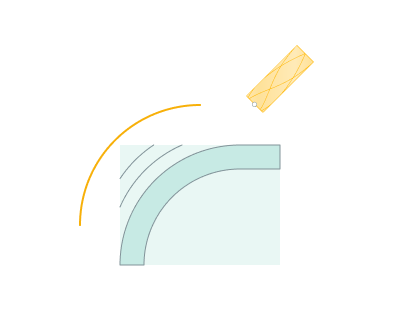

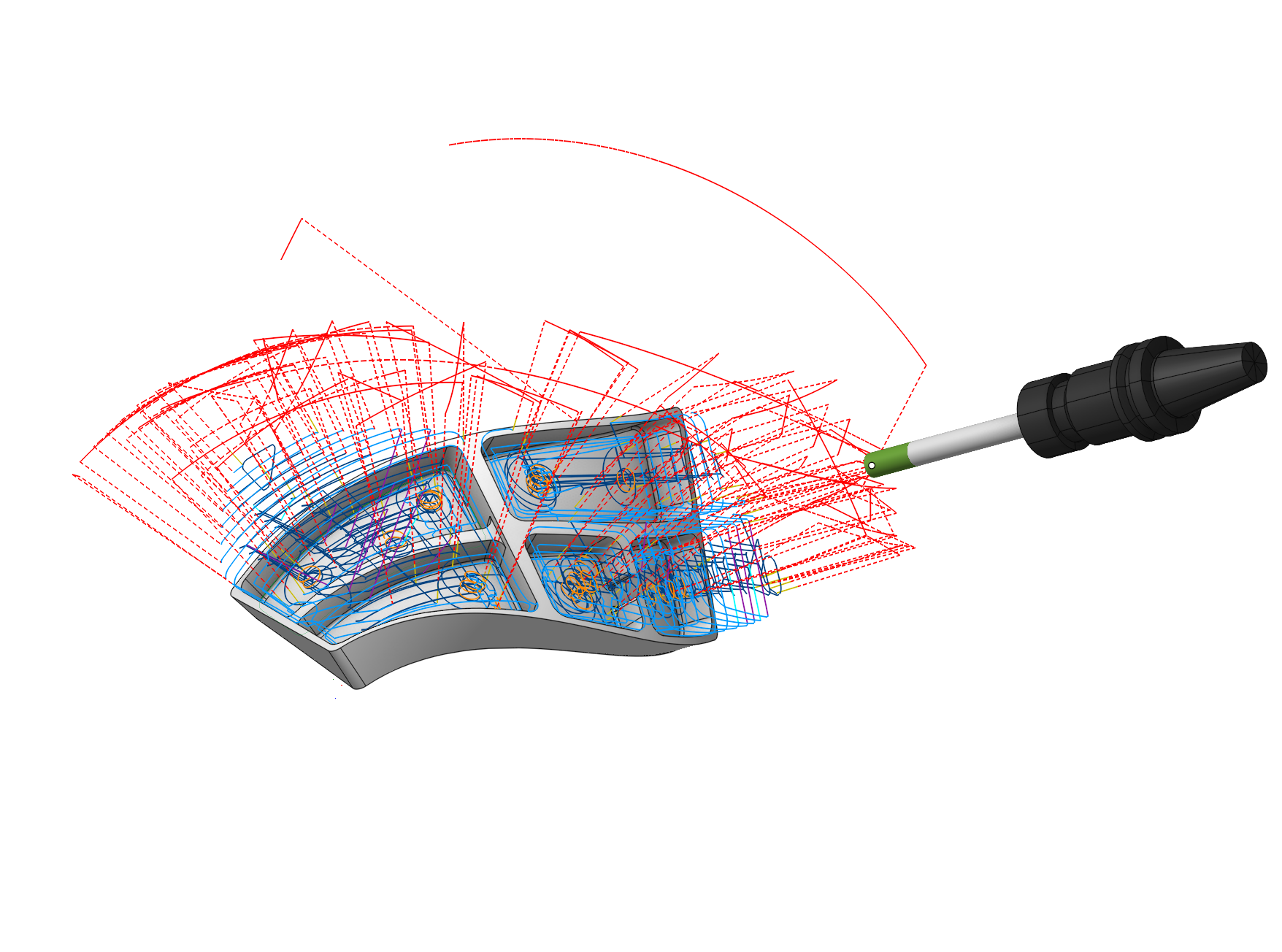

5D Roughing waterline

Application area:

Specialized processing for pockets with curved bottoms, based on the Waterline operation.

Job assignment:

Floor surfaces. Control surface. Typically defined by the pocket bottom.

Job Zone curve. Job zones are used to define the part areas that have to be machined by roughing and finishing milling operations. In this operation, only a closed work zone is applicable. See more

Properties. Displays the properties of an element. It is possible to add the stock. You can also call this menu by double clicking on an item in the list.

Delete. Removes an item from the list.

Restrictions. It allows you to restrict areas that should not be machined. See more

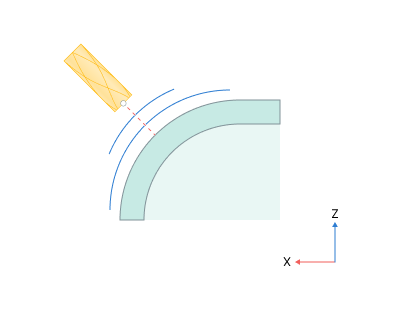

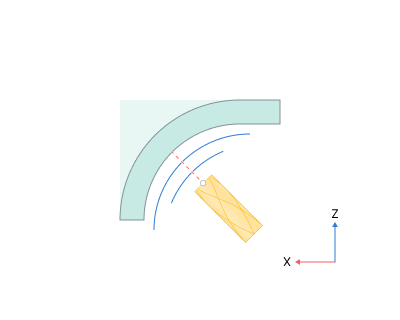

Strategy:

Strategy.

This parameter allows the user to achieve a toolpath that appears adaptive or equidistant when performing pocketing operations. This parameter group works similarly to the Waterline roughing operation. See more

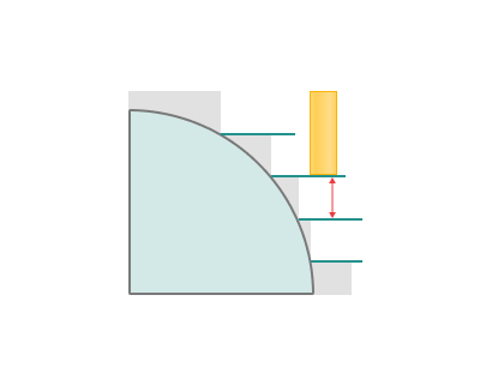

Machining levels.

It defines the range along tool axis for the machining.

Face side.

Determines the machining direction from the bottom surface of the pocket.

Depth Step.

Material removed in one pass along the tool axis between the Top and Bottom levels.

Milling type.

Сan be assigned in almost all operations, except for the curve machining operations. This allows the user to control the required milling type (climb or conventional) during the toolpath calculation process. This parameter group works similarly to the Waterline roughing operation. See more

Links/Leads:

In the Links/Leads tab, you define the parameters for rapid movements. These movements include tool approach from the tool change position, engage to the start of the working stroke, retraction after the final cutting motion, transitions between working passes, and return to the tool change point. You can configure the sequence of movements along the coordinates, the trajectory of these motions, and the magnitude of displacements.

Feeds/Speeds:

Using this dialogue the user can define the spindle rotation speed; the rapid feed value and the feed values for different areas of the toolpath. Spindle rotation speed can be defined as either the rotations per minute or the cutting speed. The defining value will be underlined. The second value will be recalculated relative to the defining value, with regard to the tool diameter. See more

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more

Part:

A Part is a group of geometrical elements that defines the space to check for gouges. See more

Workpiece:

A workpiece model of an operation defines the material to be machined. See more

Fixtures:

As the Fixtures the fixing aids such as chucks, grips, clamps, etc., and the restriction areas of any other nature are usually specified. See more