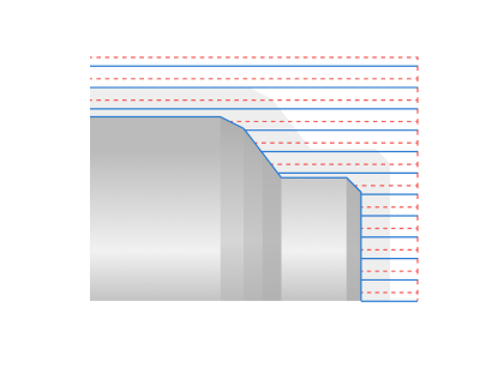

Adaptive roughing (turning)

Application Area:

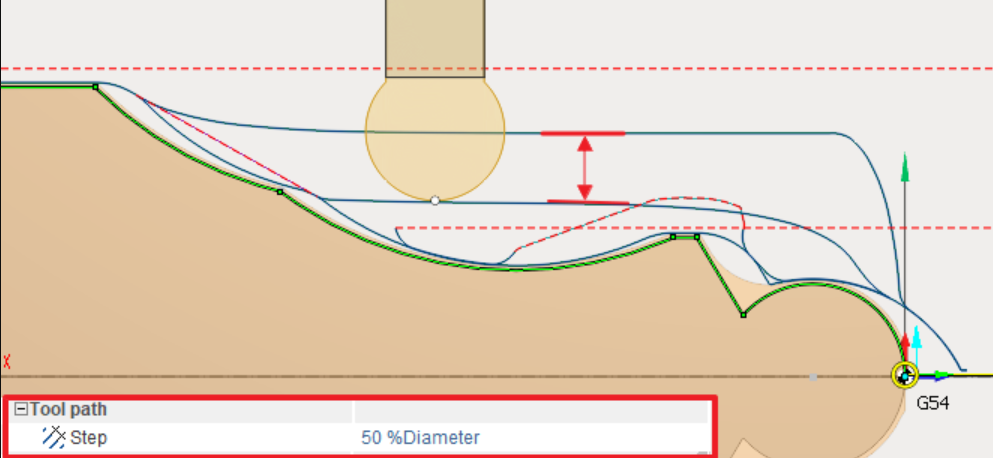

The operation generates an optimized smooth trajectory that maintains constant tool load, extending tool life and significantly increasing processing speed through higher cutting feed rates.

The turning process executes more than twice as fast compared to the traditional Grooving cycle.

This cycle adopts the Adaptive strategy from the Waterline Roughing operation, with all parameters mirroring this strategy.

It uses

tool with round insert

.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Job Assignment:

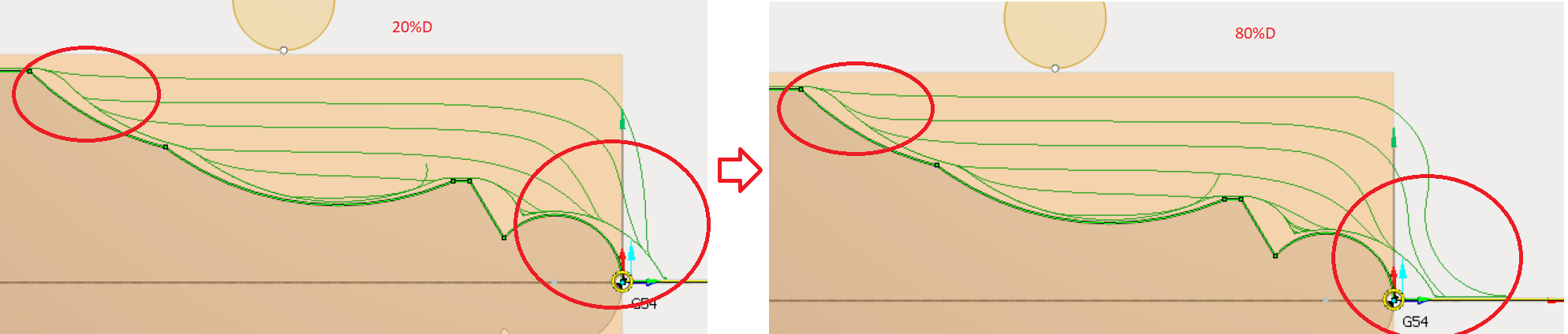

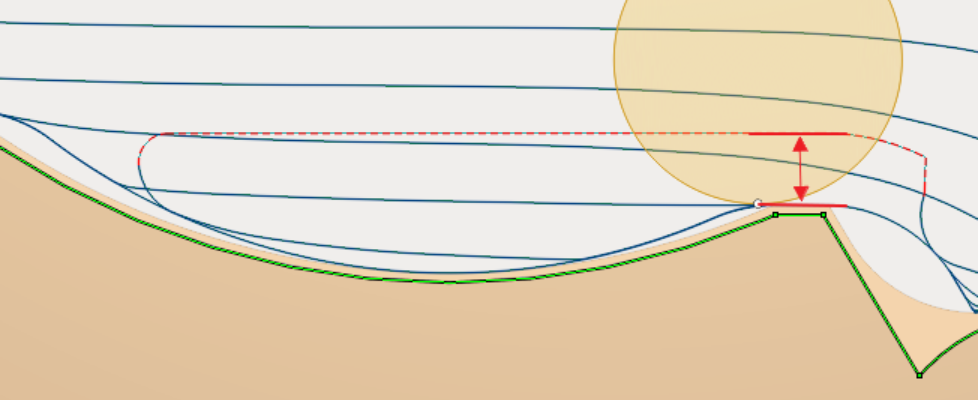

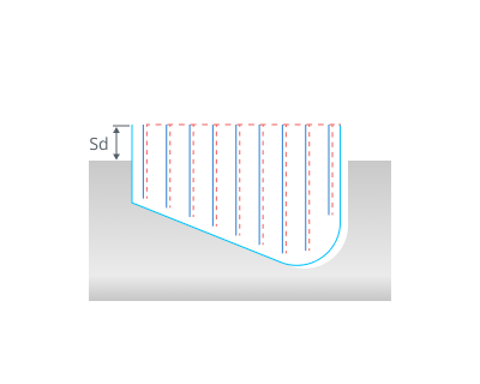

Adaptive. The process uses high feed rates with a small step, rounded passes, and avoids sharp edges in the toolpath. It incorporates a roll-in technique for entering the tool, which is less stressful on the tool. The method supports processing in both forward and backward directions.

Properties. Displays the properties of an element. It is possible to add the stock. You can also call this menu by double clicking on an item in the list.

Delete. Removes an item from the list.

CycleParams:

Cycle.

Only an Adaptive cycle is available for this operation.

Direction.

Defines direction of work passes.

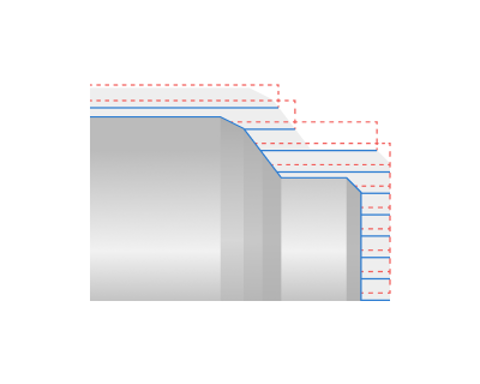

Roll by arcs.

The system rounds the external corners of the toolpath by arcs with a radius equal to the tool nose radius. The parameters group works similarly to the OD Roughing and ID Roughing operations. See more

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more.