<SINGLETHREAD> command

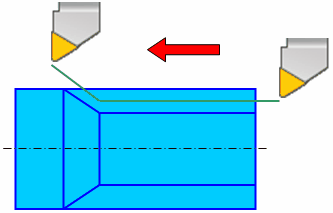

< SINGLETHREAD > command is used in continuous cylindrical or conical thread cutting with constant step by a lathe tool. Commonly this is the G32 or G33 G-codes in NC-programs.

When the threading mode is activated the tool movement and spindle rotation synchronization mode is activated. All following movements of the tool are performed in this mode until feed rate change (< FEDRAT >) command or rapid travel (< RAPID >) command is received. If the tool is traveling along the spindle axis then cylindrical thread is formed. If the tool is traveling along the spindle axis and also perpendicular to it then conical thread is machined. It is possible to machine a face thread by moving the tool only perpendicularly to the spindle axis.

< SINGLETHREAD > command parameters define the threading orientation, the thread pitch and the spindle start angle.

There are two ways to specify the thread pitch: by specifying the value of the pitch, or by specifying the number of thread turns per length unit.

Spindle start angle is specified in degrees and defines the angle that is laid off the zero signal of the spindle probe before thread cutting. Specify different angle values for different passes to machine multi-start thread.

Command :

SINGLETHREAD OD(0) | ID(1) | FACE(2), STEP(0) | COUNT(1), s, ANGLE a

Parameters :

|

Parameter |

Description |

||

|

OD(0) ID(1) FACE(2) |

CLD[1] |

CLD.Orientation |

Threading orientation: OD(0) – external, ID(1) – internal, FACE(2) – face. |

|

STEP(0) COUNT(1) |

CLD[2] |

CLD.IsCount |

Thread pitch defining: STEP(0) – value, COUNT(1) – number of thread turns per length unit. |

|

s |

CLD[3] |

CLD.Value |

Thread pitch value. |

|

a |

CLD[4] |

CLD.StartAngle |

Spindle start angle (for multiple-start thread). |

See also:

Technology commands description

Lathe threading cycle G76 <LATHETHREAD>

Lathe threading single pass cycle G92 - <LATHETHREADG92(404)>