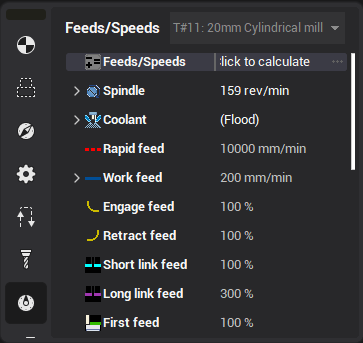

Feed types

In machining operations the user can set feed values for every type of tool movement. The number and the set of definable feeds depend on the operation type. Feeds can only be defined for those types of moves that are available for the current operation. It is possible to define the following feed types:

<Rapid feed> – feed at which all rapid tool transitions (positioning) are performed. The value is used for the calculation of the machining time and also during creation of NC code for controls that it is necessary to define the rapid feed value. When creating an NC program for machines that positioning speed depends on the drive speed, the rapid feed value is ignored;

<Work feed> – feed at which the main work passes of an operation are performed. In roughing operations material removal will be performed, in finish – detail surface machining;

<Approach feed> – feed, on which approach to the work pass beginning is performed;

<Retract feed> – feed, on which retraction after completion of a work pass is performed;

<Plunge feed> – on this feed, plunging to a lower machining layer in waterline roughing and pocketing operations is performed;

<Feed to next> – feed, on which step-over along the being machined surface to the next work pass is performed;

<Retrace feed> – feed, on which return to the previous work pass, along the toolpath of the earlier completed step-over is performed;

<Finish pass feed> – feed, on which work passes along the detail surface in rough operations are performed. It is advised to use when need to obtain a surface of high quality after a roughing operation;

<First pass feed> – feed of the first from the workpiece surface machining stroke in the rough operations. It is recommended to assign, for example, with different machinability of surface and workpiece core;

<Transition on safe surface> – feed for a toolpath that transitions on a safe surface;

<Return to safe surface> – feed for a toolpath that return to safe surface;

<Approach from safe surface> – feed for a toolpath that approach from safe surface;

<Long transition> – feed for long transitions between passes;

Feed value can be either permanent or calculated, depending on the slope angle of every elementary toolpath section. When assigning a calculated feed, defining will be feed values and coefficients when moving down, horizontally and up. The real feed values when moving down, horizontally or up will be equal to multiplication of the corresponding correction coefficient to the feed value. With intermediate values of slope angle of an elementary toolpath section, the real feed value will be calculated proportionally to the defined border values. For example, with a feed values equal to up 300, horizontally – 200, down – 100, the real feed value on a section with tool movement up under angle of 45 degrees will be equal to 250. Use of the calculated feed, allows the user to decrease the machining time due to more flexible control over cutting modes.

If in the used CAM system configuration there is the cutting modes calculation module, then feed value can be calculated automatically, regarding the workpiece material, tool and operation parameters. When using the calculated feed, the real feed values when moving up, horizontally and down will be calculated by multiplying the obtained feed value onto the corresponding coefficients.

Rapid feed can be assigned by the permanent value only. The work feed can be either permanent or variable; its real value can be assigned manually or calculated automatically by the cutting modes calculation module. All other feeds are assigned either analogously, or in percents from the work feed. When assigning in percents from the work feed, the feed type will be set just as for the work feed, and numeric values will compound the defined percent from the corresponding values of the work feed. For example, upon setting the approach feed equal to 50% from the work feed, the approach will be performed at half the feed speed of the main work passes.

See also: