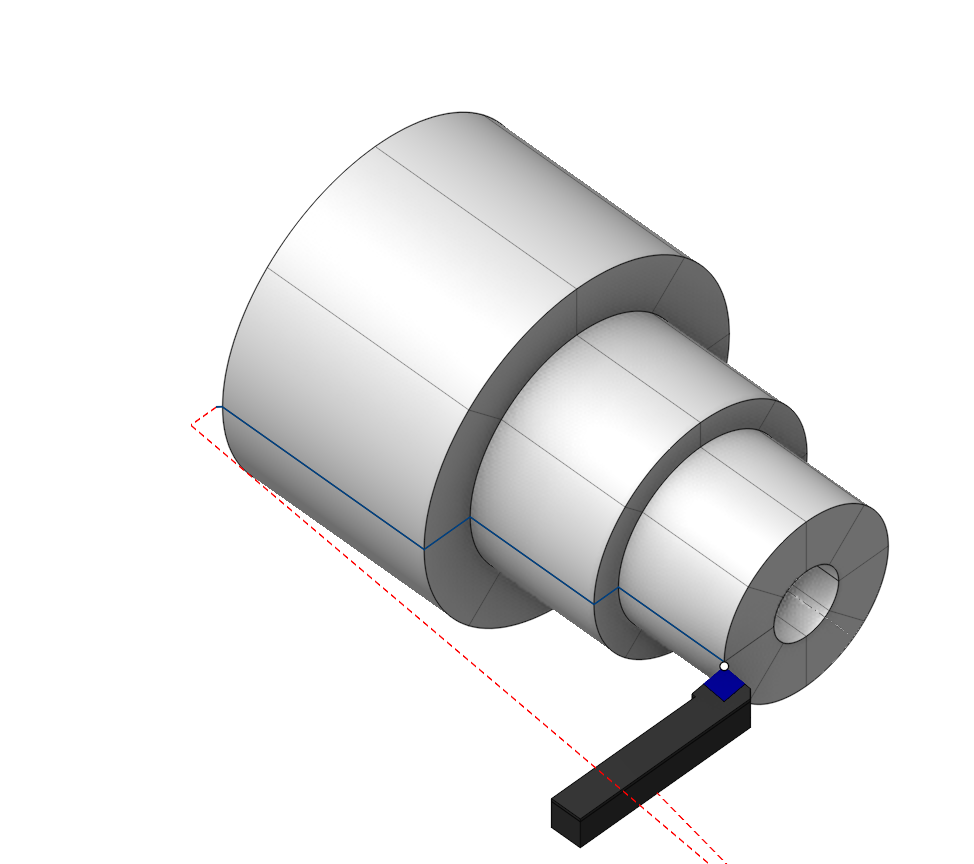

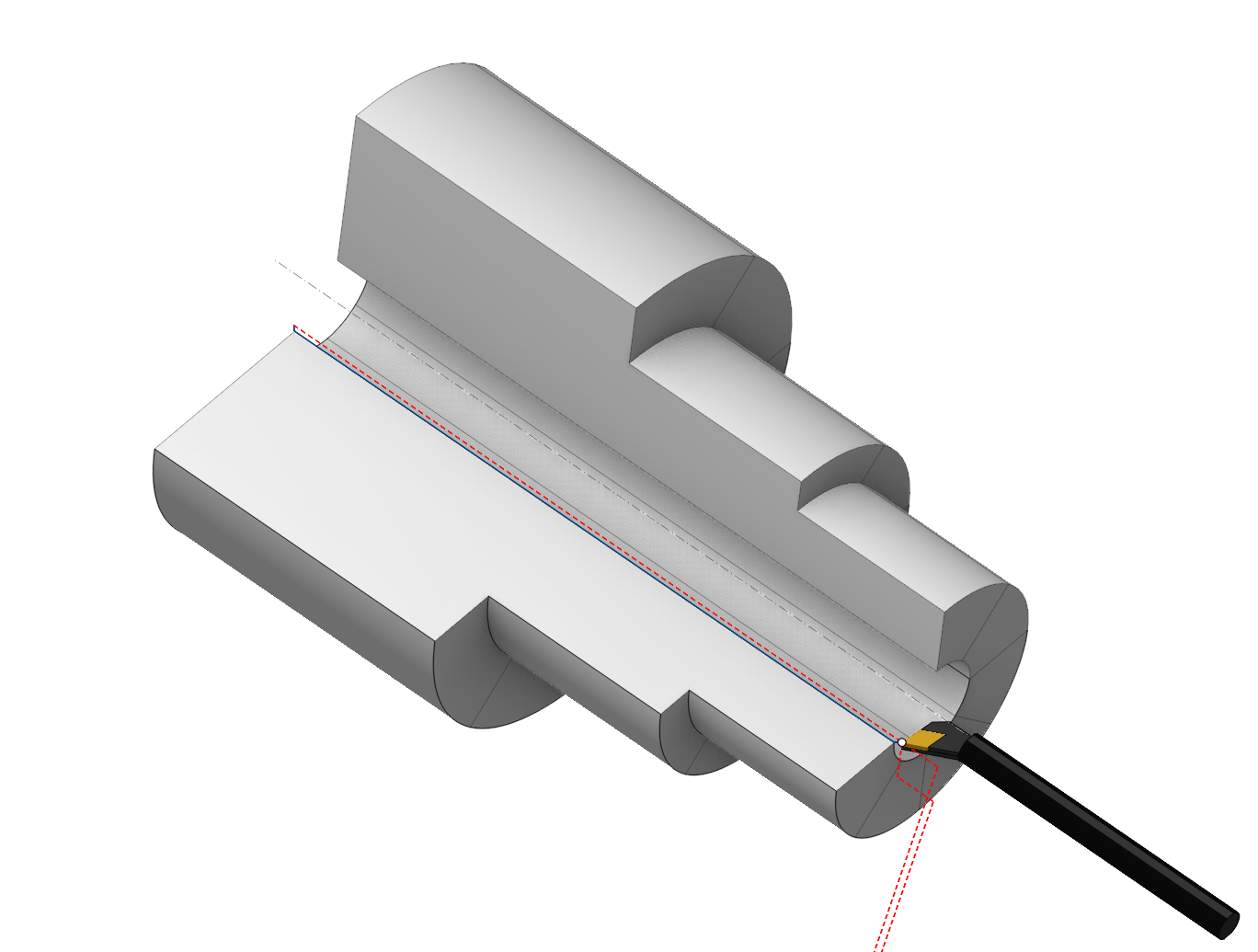

OD Finishing and ID Finishing operations

Application area:

The lathe finishing operations are designed for the removing of a small stock volume that is remained after the previous machining. The machining is performed by the series of the offset strokes to the part generatrix.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Job assignment:

Roughing. The roughing allowance is removed by tool movements along the axis of the workpiece (when processing surfaces elongated in the direction of the Z-axis) or perpendicular to it (when processing surfaces elongated in the direction of the X-axis). In other words, a trajectory is formed similar to ISO G71/G72, but it is output to the control program in an expanded form, without the use of a cycle. See more

Roughing cycle. Similar to rough machining, but the operation is output to the control program in the form of a cycle, similar to ISO G71/G72. The roughing cycle allows the creation of one of the ISO G71 or ISO G72 cycles based on the specified contour of the workpiece. Switching between G71 and G72 is achieved by changing the Direction of tool movements (along the axis of the workpiece Axial or perpendicular to it Radial) in the parameters. See more

Offset Roughing. The roughing allowance is removed by tool movements equidistant to the contour of the workpiece. In other words, a trajectory is formed similar to ISO G73, but it is output to the control program in an expanded form, without the use of a cycle. See more

Offset cycle. Similar Offset Roughing, the operation is output to the control program in the form of a cycle, similar to ISO G73. See more

Zigzag. This process is used for machining enclosed areas from both sides, using a neutral tool. The tool is engaged by plunging downwards and performs a horizontal movement to remove the next layer. The tool re-engages by plunging again and makes a horizontal pass in the opposite direction. This way, the entire roughing allowance is removed layer by layer through horizontal passes with alternating directions. See more

Profile. This is the simplest type of cycle, where a single pass is generated, and its trajectory is identical to the specified initial geometric contour of the workpiece. Only minor modifications to the contour can be performed, including approach and retract linking, offsetting by specified allowances, excluding shaded areas that cannot be reached by the designated tool, and compensating for the tool radius. See more

Facing. This allows programming the machining of the end face of a workpiece with a single command. The trajectory is formed in the same way as when specifying Contour or Contour Repeat cycles. However, the trajectory is automatically calculated based on the current blank and workpiece, ensuring correct machining of either the left or right end face. See more

Properties. Displays the properties of an element. It is possible to add the stock. You can also call this menu by double clicking on an item in the list.

Delete. Removes an item from the list.

CycleParams:

This parameter group works similarly to the OD Roughing and ID Roughing operations. See more

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more

See also: