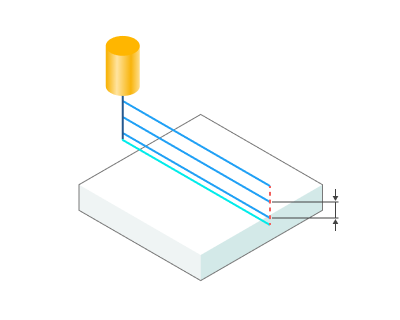

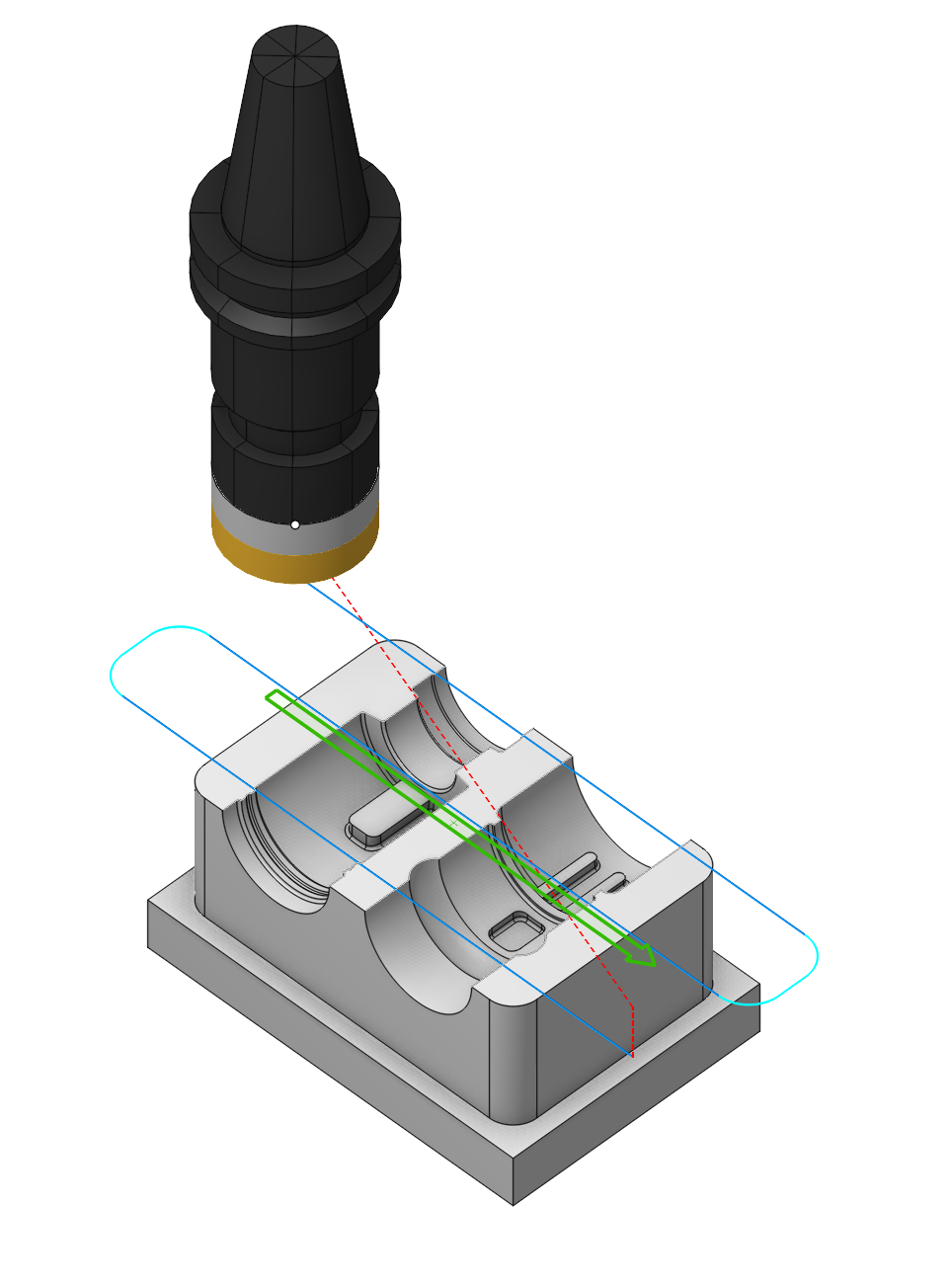

Face milling

Application area:

A facing operation removes workpiece material on a specified horizontal plane using one of the following strategies:

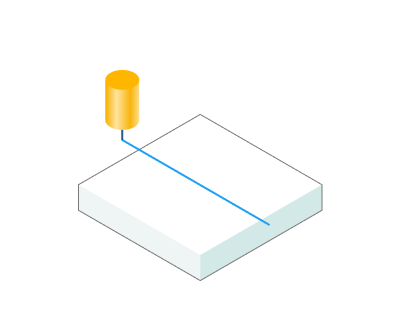

One pass

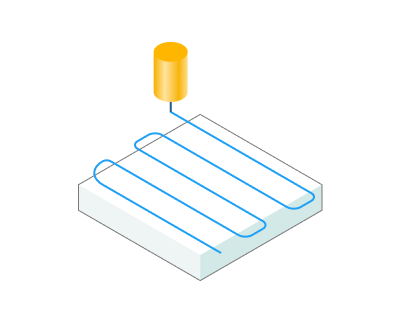

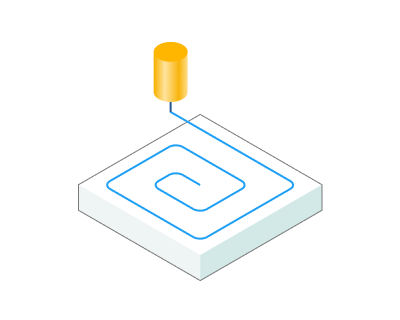

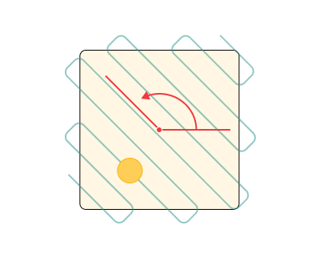

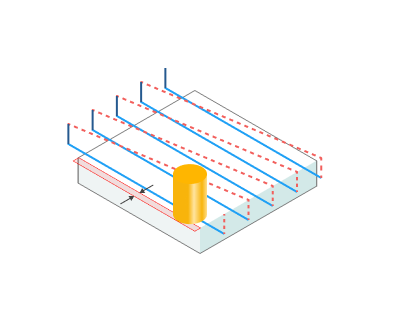

Parallel,

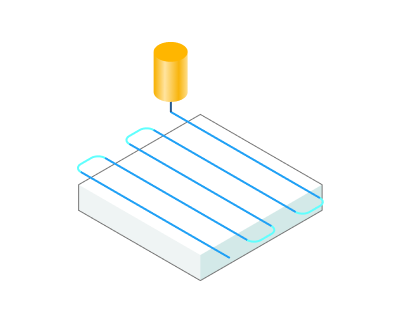

Zigzag,

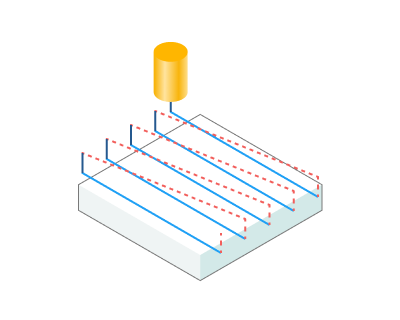

Optimized zigzag,

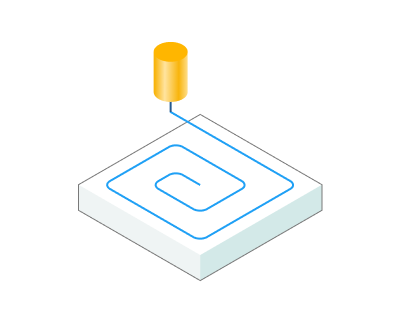

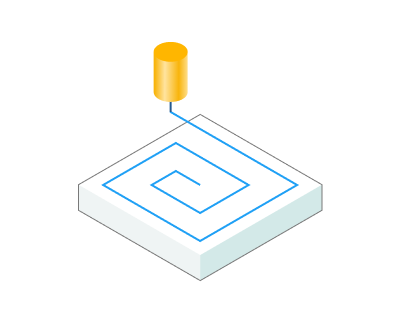

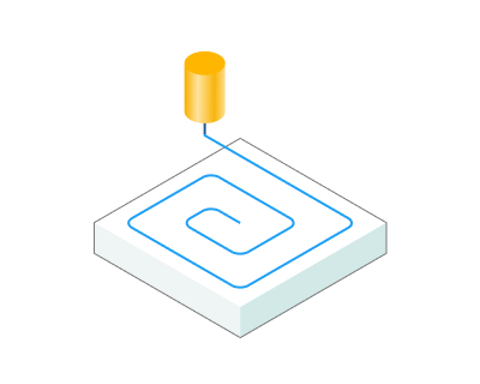

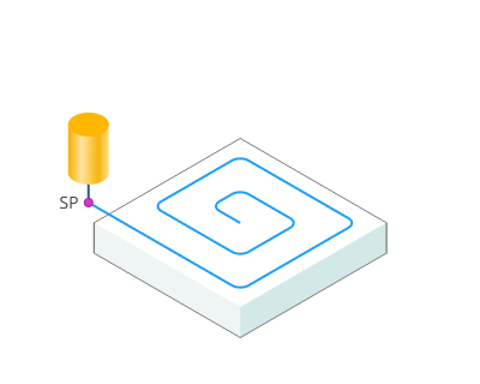

Spiral.

The geometry of the part is ignored, only the shape of the workpiece is taken into account during the operation calculation process. The part is not controlled for undercuts.

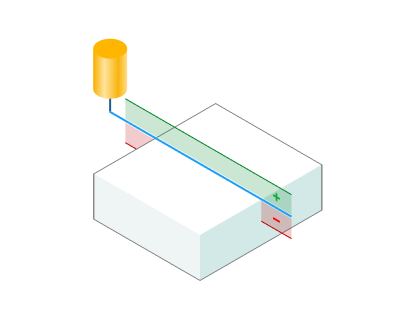

Material can be removed in multiple passes. In this case, the lower processing level is determined by default by the highest point of the part, and the upper level is determined by the highest point of the workpiece. The number of passes is calculated automatically depending on the distance between the upper and lower processing levels, the size of the finishing and the depth of the roughing passes. It is also possible to set the number of passes manually. In this case, the processing step will be recalculated.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Strategy:

Strategy.

This group allows the user to modify the primary parameters of the parallel passes strategy.

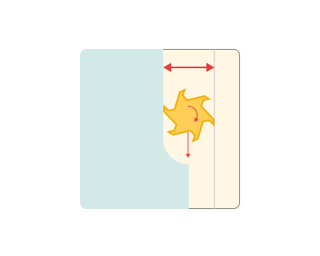

Milling type

Сan be assigned in almost all operations, except for the curve machining operations. This allows the user to control the required milling type (climb or conventional) during the toolpath calculation process. This parameter group works similarly to the Waterline roughing operation. See more

Sorting.

Controls the sequence of toolpath passes during the surface machining .

Machining levels.

It defines the range along tool axis for the machining. This parameter group works similarly to the Waterline roughing operation. See more

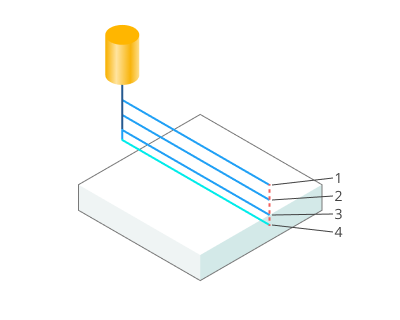

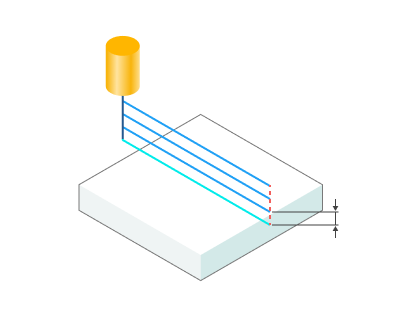

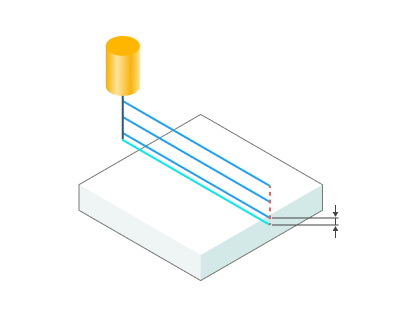

Nb. of passes

The number of machining passes. By default this is computed automatically based upon the top and the final levels for machining, the Cleanup height and the Depth Step.

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more