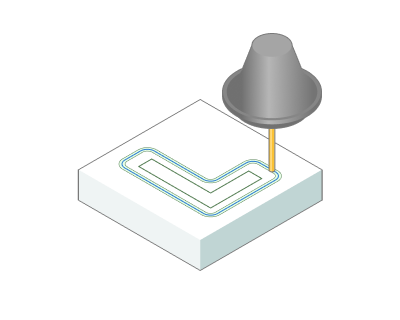

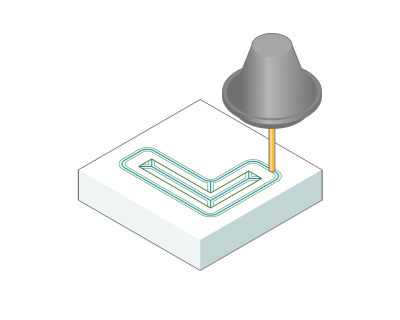

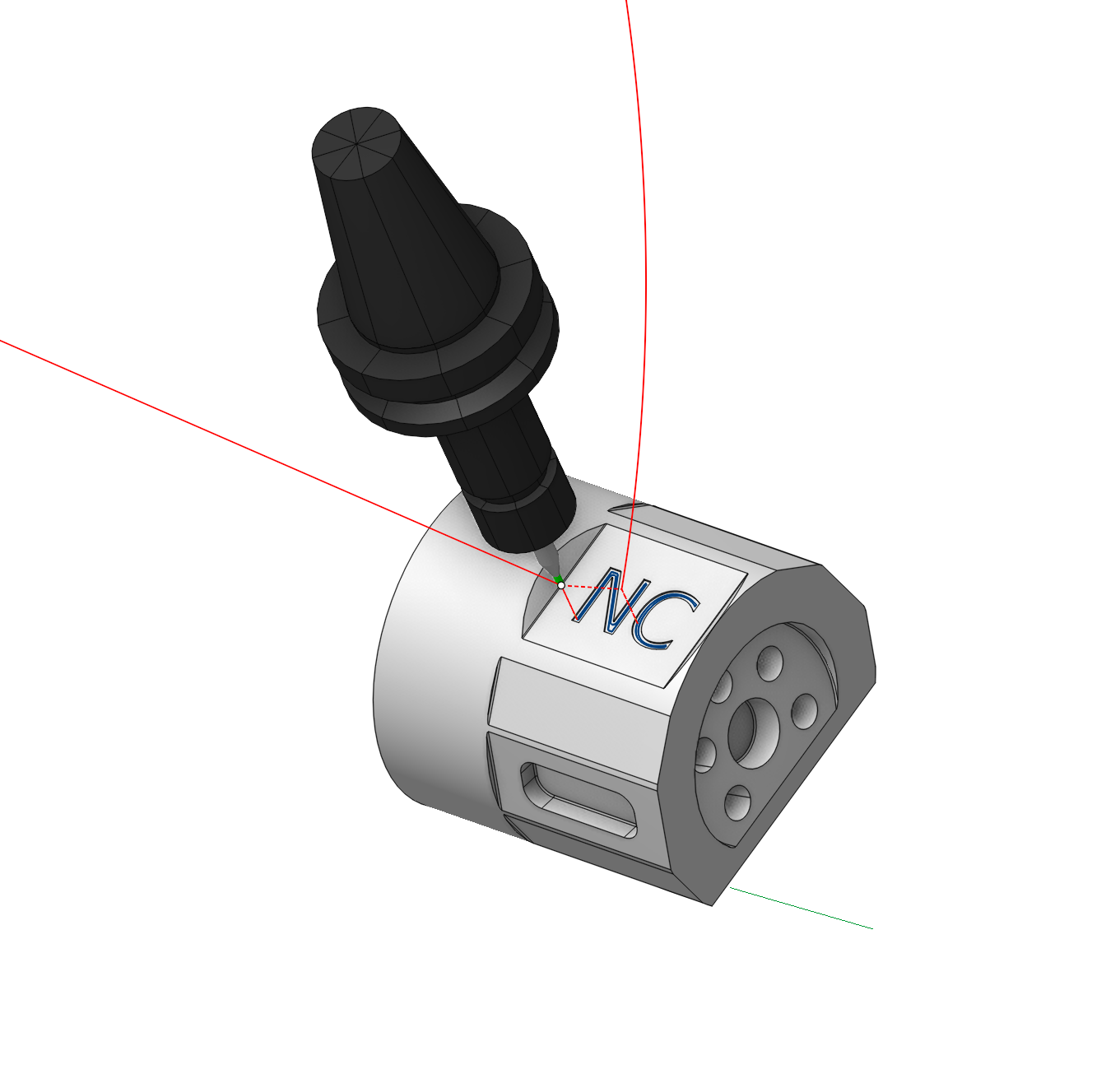

Engraving operation

Application area:

This operation is designed for the engraving of drawings and inscriptions on flat areas, and also for performing a finish pass along the side walls of pockets and contours using 2 / 2.5D machining.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Job assignment:

Base surface. This surface serves the purpose of projecting a trajectory onto it. See more

Add Boss. Allows you to add a boss. See more

Add Pocket. Allows you to add a pocket. See more

Add Inversion. Indicates a closed area, inside which the machining rules will be reversed, i.e. machined areas will become unmachined and vice versa. See more

Top Level. Specifying the top level by model elements. See more

Bottom Level. Specifying the bottom level by model elements. See more

Properties. Displays the properties of an element. It is possible to add the stock. You can also call this menu by double clicking on an item in the list.

Delete. Removes an item from the list.

Strategy:

V Carving.

It adds additional passes to the trajectory to achieve a higher quality result, which is particularly effective for creating small elements.

Machining levels:

It defines the range along tool axis for the machining. This parameter group works similarly to the Waterline roughing operation. See more

Depth Step:

Material removed in one pass along the tool axis between the Top and Bottom levels. This parameter group works similarly to the Pocketing .

Milling type:

Сan be assigned in almost all operations, except for the curve machining operations. This allows the user to control the required milling type (climb or conventional) during the toolpath calculation process. This parameter group works similarly to the Waterline roughing operation. See more

Sorting:

Controls the sequence of toolpath passes during the surface machining .. This parameter group works similarly to the 2D contouring. See more

Corners:

When there is a sudden change of the tool direction, the milling control performs deceleration before starting the turn, and then accelerates again. This fact can lead to vibrations and high tool and milling machine wear. The problem can be solved if the toolpath has very few or no breaks. For this reason, in the system there is the toolpath smoothing function using the defined radius for machining inner or outer corners of the model.

Some parameter group works similarly to the 2D contouring - Corners smoothing . See more

Job zone:

Enables additional modification of the working area initially selected on the Job assignment tab. This parameter group works similarly to the Plane finishing operation. See more

Transformations.

A dialogue for transforming the toolpath. This parameter group works similarly to the 2D contouring. See more

Transformations:

Parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool. See more

See also:

Operation for 2/2.5-axes milling

4-axis milling with using of the engraving and pocketing operations

Using design features in an Engraving/Pocketing operation

Job assignment for engraving and pocketing operations