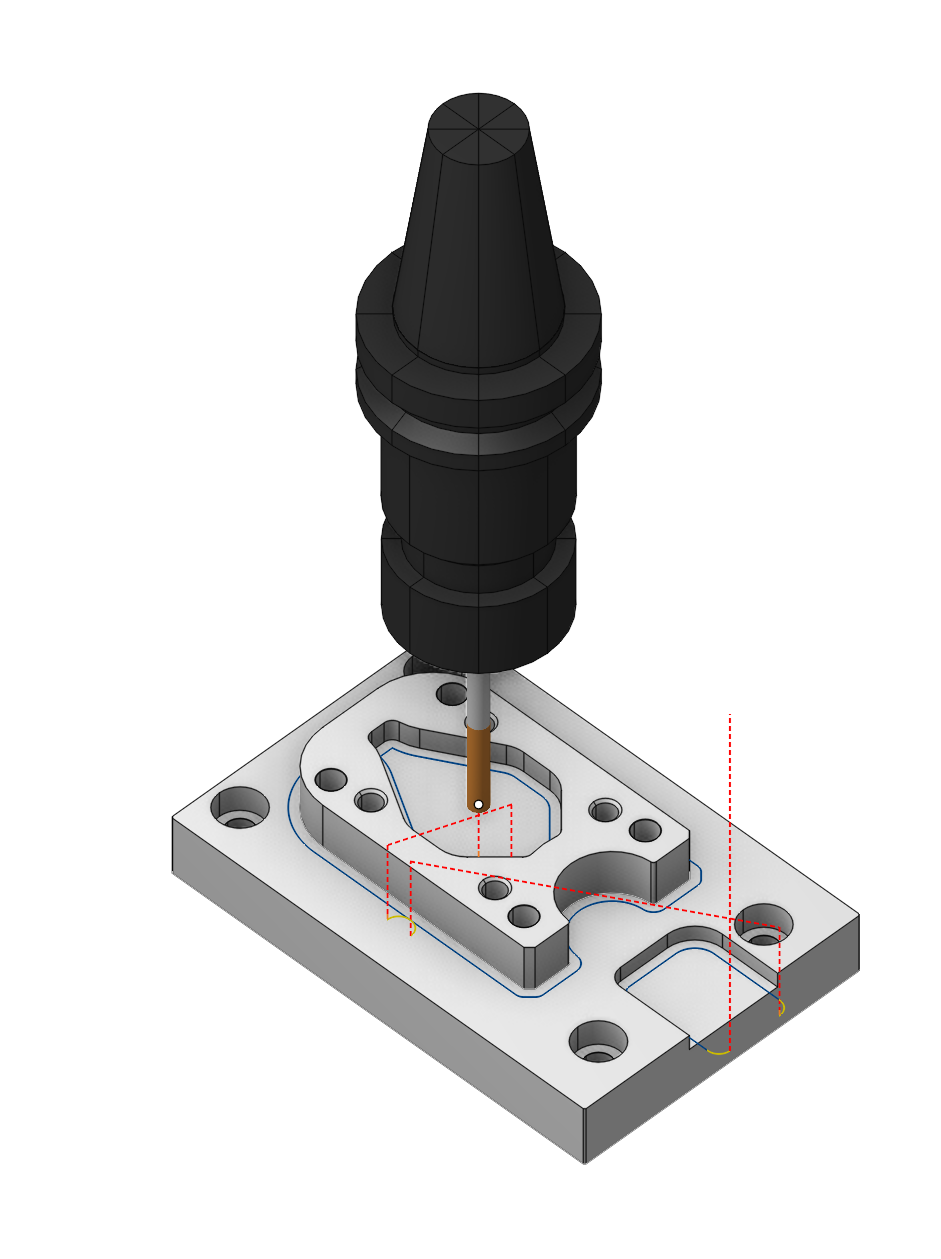

2.5D contouring

Application area:

This operation extends the capabilities of the 2D contouring operation in terms of machining multi-level contours of parts. Main the functionality of the 2D contouring operation was preserved.

Setup:

The Setup tab is used to configure the primary parameters of the project. This can involve the positioning of the part on the equipment, the coordinate system of the part, and more. See more

Job assignment:

Curve. Set work order along curve . See more

Pocket. A typical prismatic or turn-milling part consists of many simple shapes.To simplify this task, we can recognize the parts elements in a 3d model and automatically convert them to basic job assignment items, such as job zones and machining levels. See more

Properties. Displays the properties of an element. It is possible to add the stock. You can also call this menu by double clicking on an item in the list.

Add tabs. Adds tabs along the contour. See more

Delete. Removes an item from the list

Strategy:

The main parameters of the operation Strategy are described in the 2D contour section. See more

See also: