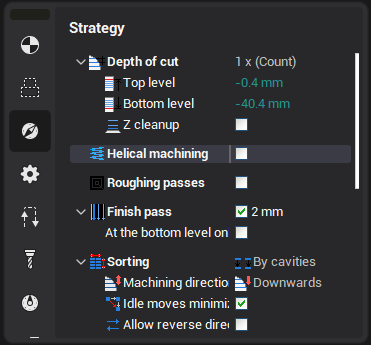

Helical machining

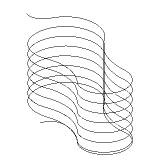

When machining 2D curves it is possible to obtain a spiral-like toolpath. Thus, in the resulting NC program, a block G2/G3X:Y:Z:R: type can be inserted (depending on the postprocessor used). At the bottom machining level, the user can assign a finish pass along the entire curve. The user can also assign a smoothing value for linking the spiral and the finish pass at the bottom level. Smoothing is defined as a radius value.

The number of spiral loops depends on the Z step assigned in the <Parameters> page. If a tick is placed in the <Clean pass> box, the system will generate a horizontal toolpath area for bottom machining.

With <Smoothing> mode active, the tool transition onto the horizontal plane (bottom level) will be performed without a break along the curve using the defined radius. This function is especially useful for high speed machining.

See also: