Corner control

Application Area:

This group of parameters allows you to to add some specific behaviour to the toolpath corners. It is located on the bottom of "Feeds/Speeds" page.

Note

The corners control is only applied to the toolpath segments with an effective feed, which you can set through the "Effective feeds" parameter on the "Parameters" page.

There are two main groups of parameters that allow you to control corners: "Detection method" and "Action type".

Detection Method:

"Detection method" group of parameters shows the system how to detect corners. Now, only one parameter is available - "By angle".

By Angle.

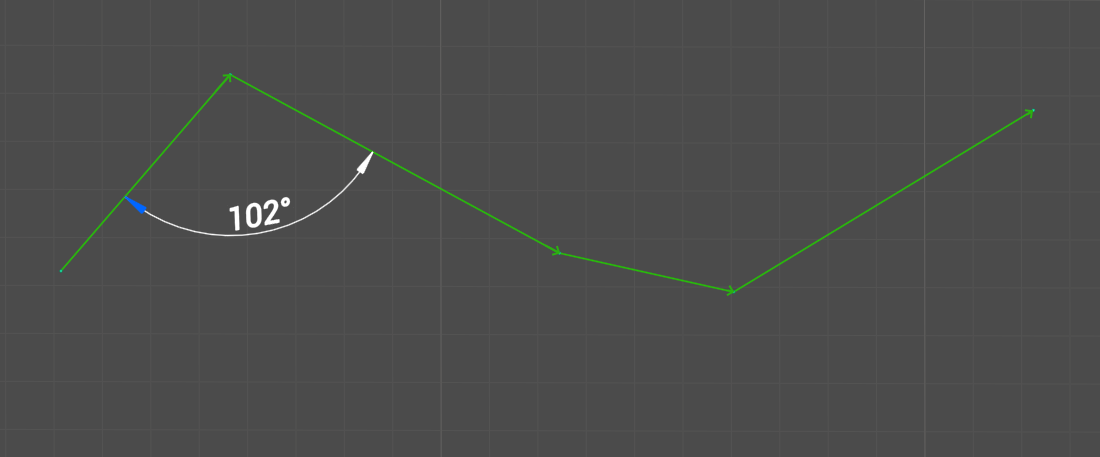

"By angle" parameter defines the angle value in degrees. Two consecutive segments of the toolpath will be detected as a "corner", if the angle value between them is less than or equal to the defined value.

For example, the first angle with a value of 102 degrees will be marked as a corner in the system if the "Angle" value is set to 110 degrees.

Also there are two additional parameters for more precise adjustment: "Minimum line length" and "Minimum arc radius".

Minimum line length parameter allows you to smooth the toolpath before running the corner detection algorithm using the desired tolerance (or we can say the minimum line length) value. So, the detection method is applied to a smoothed toolpath, which ensures there are no false corner detections or missed corners. Note: this parameter doesn't affect the final toolpath. It is only used for internal detection algorithms.

Minimum arc radius parameter allows you to set the minimum arc radius (or maximum curvature) that the system will recognize as an angle. This is because some arcs in a toolpath can be very small, and in the reality the machine will slow down on these segment.

Action Type:

"Action type" group of parameters allows you to choose how the system will behave in corners of the toolpath. Now, only one parameter is available - "Slowdown feed by steps", which consists of 3 available options: "Slowdown percent", "Number of steps", "Step length".

Slowdown Feed by Steps.

Determine the parameters that manage the step-by-step feed deceleration when passing a corner.

Slowdown percent defines the minimum feed as a percentage of the working feed in the current corner to which you need to slow down.

Number of steps defines how many steps are required to reach the minimum speed.

Step length defines the length of one step.

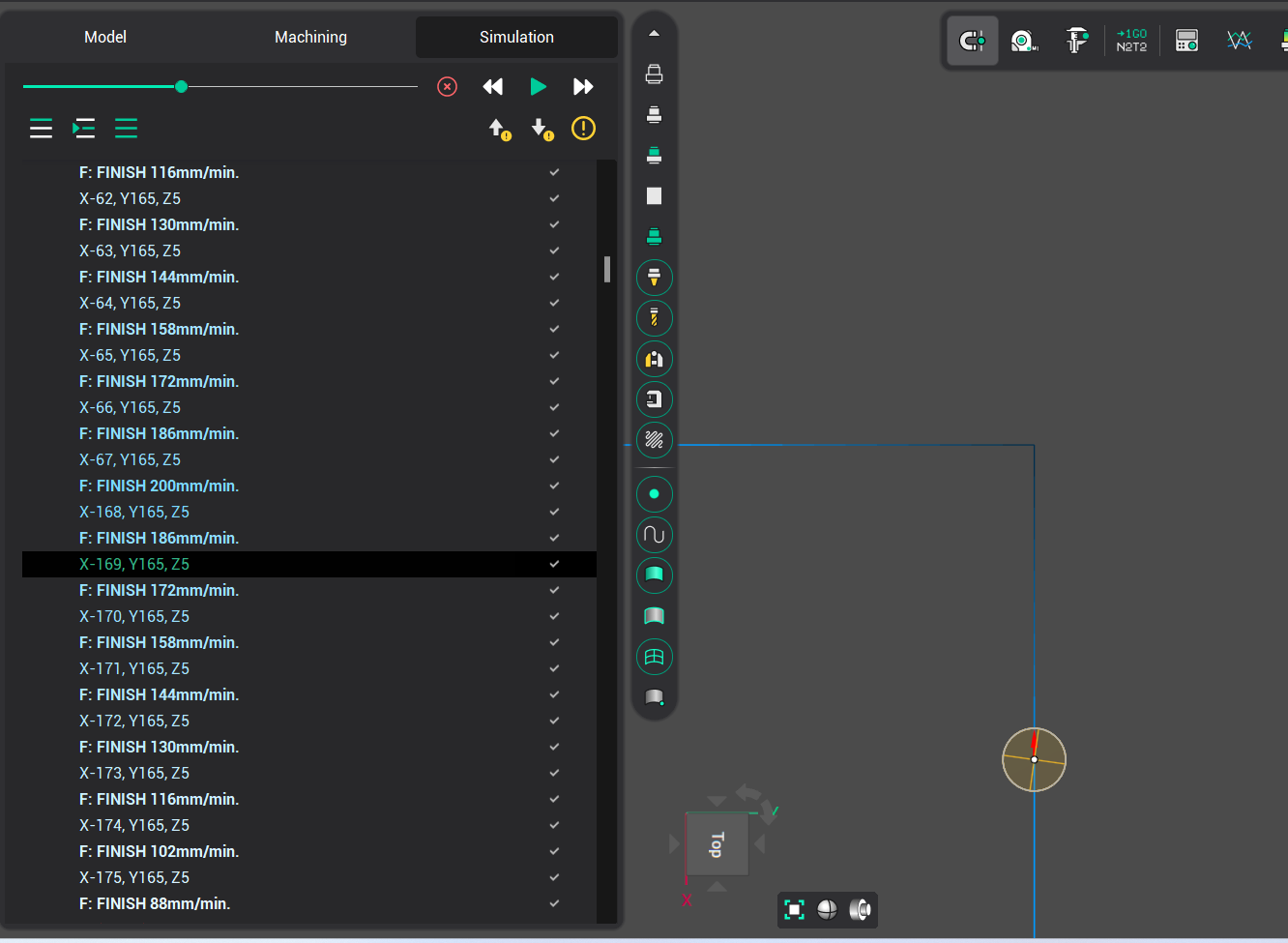

The result of working with these parameters can be seen on the "Simulation" page. Toolpath segments in the corners will be marked with a color gradient. Also, you can see new commands added to CLDATA with reduced feed and also marked with a color gradient.