Bar feeding

Operation overview

Any machining on the swiss lathe starts from the bar feeding. So the bar feeding operation must be the first in the operation list for the swiss lathes. On Hanwha swiss lathes it generates G300.

See the Creating a simple Bar feeding operation video for an example of using the operation.

Bar feeding parameters

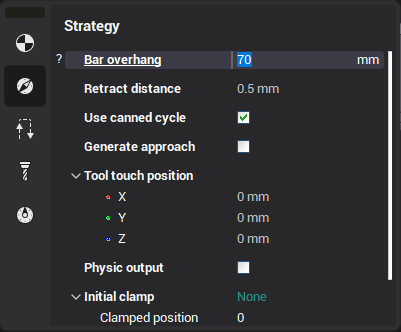

Bar overhang

The axial distance between the spindle base point and the tool tip point.

Retract distance

The rebound of the limiter-tool before move it away.

Use canned cycle

Whether the bar transferring process will be formalized as a cycle for the further analysis in the postprocessor or will be output as a sequence of elementary commands.

Generate approach

Disable this parameter if the tool is already located in the start point after cut-off, for example, in the case of the looped program.

Tool touch position

The touch position of the tool tip point in the workpiece coordinate system (G54).

Initial clamp

Select (optionally) the clamp device which initially holds the part and define the parameters for its usage. If enabled, special CLData commands will be generated for clamping/unclamping the part during the bar feeding. For more information about the clamp control parameters, see the Clamp devices control article.

Example project(s)

See the Turn-Milling/Hanwha sample project where the Bar feeding operation is used to initially position the part for further machining.

See also:

Machine requirements for part moving operations